Posts

2025 Top Cast Acrylic Uses Benefits and Applications You Need to Know

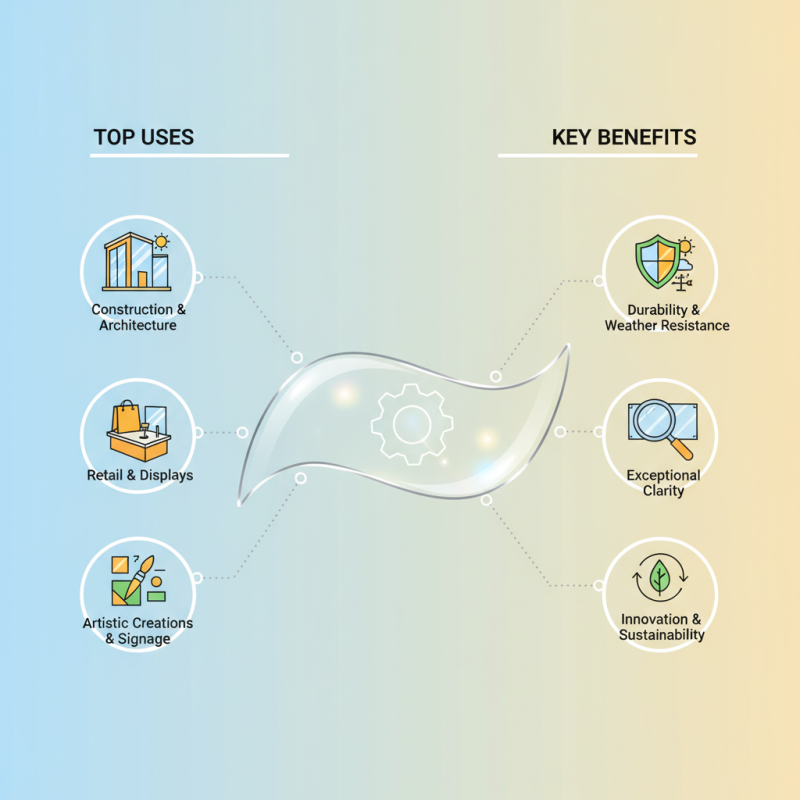

Cast acrylic, often recognized for its clarity and versatility, has emerged as a prominent choice across various industries. As we approach 2025, understanding the multitude of uses, benefits, and applications of cast acrylic becomes increasingly important for designers, architects, and manufacturers alike. This unique material offers an array of functionalities, making it suitable for everything from artistic creations to practical uses in construction and retail.

One of the primary advantages of cast acrylic is its exceptional durability and resistance to weathering, which makes it ideal for both indoor and outdoor applications. Whether you're considering it for signage, protective barriers, or decorative elements, cast acrylic's adaptability helps transform ideas into reality while maintaining longevity. As we explore the top applications of cast acrylic, it becomes evident that its contributions will continue to influence various sectors, promoting innovation and sustainability in design. Through this journey, we will highlight the key benefits that position cast acrylic as a material of choice in contemporary projects.

Top Benefits of Cast Acrylic for Various Industries in 2025

In 2025, cast acrylic continues to revolutionize various industries due to its remarkable array of benefits. One of the most significant advantages of cast acrylic is its lightweight nature, which makes it a preferred alternative to glass. This property not only enhances ease of handling and installation but also reduces shipping costs, making it an economically viable option for manufacturers. Furthermore, cast acrylic is inherently shatter-resistant, providing a safer solution in applications where breakage poses a risk, such as in construction, automotive, and safety equipment.

Another critical benefit of cast acrylic is its outstanding optical clarity and ability to transmit light. This makes it an excellent choice for applications where visibility is paramount, such as in signage, display cases, and aquariums. The material also boasts a high level of weather resistance, allowing it to maintain its transparency and structural integrity even in harsh outdoor environments. As industries increasingly prioritize sustainability, cast acrylic’s recyclable nature adds to its appeal, making it a responsible choice for eco-conscious projects.

The combination of durability, aesthetic appeal, and environmental considerations positions cast acrylic as a material of choice for a wide range of applications in 2025 and beyond.

Key Applications of Cast Acrylic in Architecture and Design

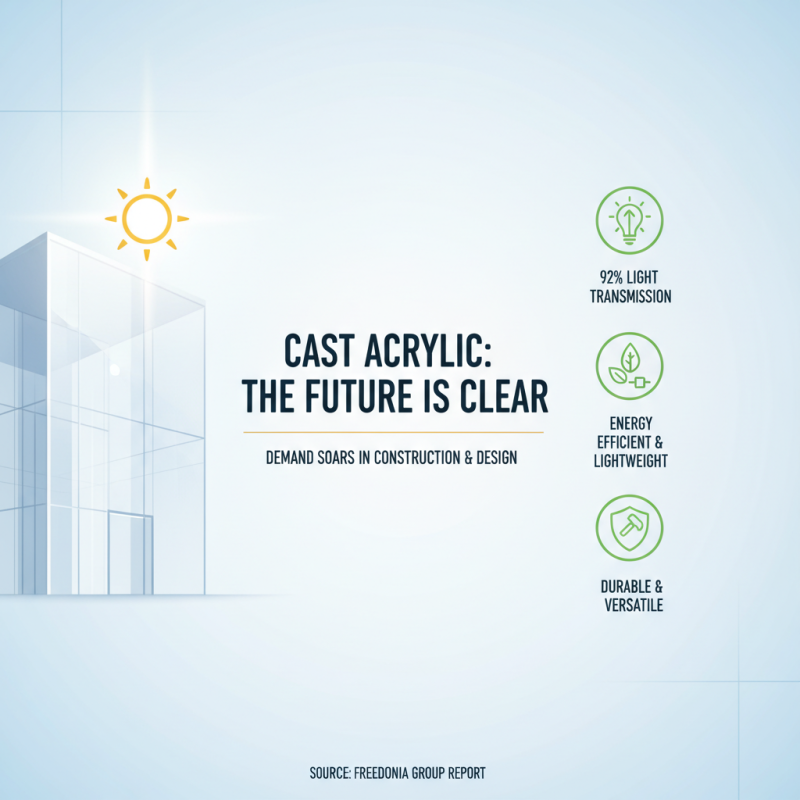

Cast acrylic, known for its crystal clarity and robust properties, is increasingly being utilized in architecture and design. According to a report by the Freedonia Group, the demand for cast acrylic in construction and design is anticipated to soar, driven by its lightweight nature and versatility compared to traditional materials like glass. Architects are turning to cast acrylic for facades, partitions, and skylights, given its excellent light transmission of around 92%, which allows for expansive natural lighting while maintaining energy efficiency.

One significant application of cast acrylic in architectural design is in the creation of modern interiors and environmental elements. Its ease of molding and customization allows designers to create unique shapes and structures, enabling innovative designs that enhance aesthetic appeal. A study from Market Research Future indicates that the architectural segment alone is expected to witness a growth rate of 6.5% from 2020 to 2026. Moreover, the material’s durability ensures that it can withstand various environmental conditions, making it a reliable choice for both outdoor and indoor applications. These properties not only contribute to the overall sustainability of building projects but also open up new possibilities for creative exploration in architectural design.

Impact of Cast Acrylic on the Automotive Sector in 2025

The automotive sector is poised for a transformative shift in 2025, largely fueled by the adoption of cast acrylic materials.

Cast acrylic, known for its exceptional clarity and high impact resistance, presents significant advantages over traditional glass and other materials. According to a report by MarketsandMarkets, the global demand for cast acrylic in automotive applications is projected to grow at a CAGR of 5.6% from 2021 to 2026. This growth is largely attributed to the increasing need for lightweight components that enhance fuel efficiency without compromising safety.

In the automotive sector, cast acrylic is being increasingly utilized in applications such as interior components, lighting fixtures, and windshields. The lightweight nature of cast acrylic, which is approximately half the weight of glass, contributes to lower vehicle weight and improved fuel economy, addressing both environmental concerns and consumer preferences for energy-efficient vehicles. Furthermore, the material’s durability ensures that vehicles maintain a sleek appearance over time, reducing the frequency of replacements and repairs. With advancements in manufacturing techniques, such as injection molding and thermoforming, the scope for innovative cast acrylic applications continues to expand, promising to enhance both vehicle design and performance by 2025.

Sustainability and Recyclability of Cast Acrylic Materials

The sustainability and recyclability of cast acrylic materials are becoming increasingly vital as industries shift towards environmentally responsible practices. Cast acrylic, known for its durability and versatility, has a lifespan that often exceeds ten years, reducing the frequency of material replacement and waste. According to a report by the Acrylic Sheet Manufacturers Association (ASMA), approximately 70% of cast acrylic products can be recycled, significantly lower in weight compared to glass, which further reduces transportation emissions.

Moreover, the recyclability of cast acrylic extends beyond single-use applications. It can be repurposed into a variety of products, including new sheets or other acrylic items, thereby contributing to a circular economy. Recent studies have shown that the recycling process for acrylic materials consumes up to 80% less energy than producing new acrylic from raw materials, an essential factor in minimizing carbon footprints. This aligns with broader sustainability goals in manufacturing, especially considering the increasing consumer demand for eco-friendly materials, with over 60% of consumers stating they prefer products that are easily recyclable.

2025 Top Cast Acrylic Uses Benefits and Applications

This chart illustrates the various applications of cast acrylic materials in 2025, showcasing their widespread usage in different fields. The percentages represent the estimated distribution of cast acrylic use across these applications, highlighting its versatility and popularity.

Comparative Analysis: Cast Acrylic vs. Other Plastics in 2025 Usage

In 2025, cast acrylic continues to stand out as a premier choice in various applications, particularly when compared to other plastics like polycarbonate and PET. Industry reports suggest that the demand for cast acrylic is projected to grow significantly, driven by its superior optical clarity and weather resistance, making it ideal for applications such as signage, displays, and protective barriers. Data from the Plastics Industry Association indicates that the global market for cast acrylic is expected to reach $2.5 billion by 2025, highlighting its essential role in a multitude of sectors including construction, automotive, and consumer goods.

When we compare cast acrylic to polycarbonate, which is often favored for its impact resistance, it becomes clear that cast acrylic offers better UV stability and is less prone to yellowing over time. A study by MarketsandMarkets predicts that while polycarbonate's market share is also substantial, cast acrylic's growth rate will outpace it due to increasing consumer preference for lightweight, durable materials that provide aesthetic appeal as well as functionality. Furthermore, with sustainability becoming an integral aspect of production, cast acrylic's recyclability is an additional benefit that enhances its competitive edge in the marketplace. These factors collectively underline the continuing relevance of cast acrylic in the evolving landscape of plastic materials.

Related Posts

-

How to Cut and Shape Cast Acrylic Sheets for Your DIY Projects

-

Discover the Benefits of Custom Cut to Size Plexiglass for Your Home and Business Needs

-

Exploring the Versatility of Cast Acrylic: Creative Applications for Modern Design

-

Transform Your Space with Custom Cut to Size Acrylic Sheets for Every Project

-

2025 Top 5 Colored Acrylic Sheets for Stunning Home Decor and DIY Projects

-

Top 5 Benefits of Using Plexiglass Sheets Cut to Size for Your Projects