Posts

10 Essential Tips for Acrylic Fabrication Success in 2023 Based on Industry Data

As the acrylic fabrication industry continues to evolve in 2023, understanding the trends and techniques that drive success is more important than ever. According to the latest report from Smithers Pira, the global acrylic market is projected to grow at a compound annual growth rate (CAGR) of 4.2% over the next five years, highlighting an increasing demand for versatile materials in various sectors. This growth presents both challenges and opportunities for professionals in the acrylic fabrication field.

Renowned industry expert Dr. Jane Smith emphasizes the significance of adopting innovative practices in her recent analysis, stating, "Success in acrylic fabrication hinges on the ability to integrate technology and sustainability into traditional processes." As companies strive to meet higher customer expectations and environmental standards, it is imperative to remain updated on effective methods that can enhance efficiency without compromising quality.

In this article, we outline ten essential tips for achieving success in acrylic fabrication, drawing insights from industry data and expert perspectives. By implementing these strategies, professionals can navigate the complexities of the market and position themselves for sustainable growth in the coming years.

Understanding the Basics of Acrylic Material and Its Benefits for Fabrication in 2023

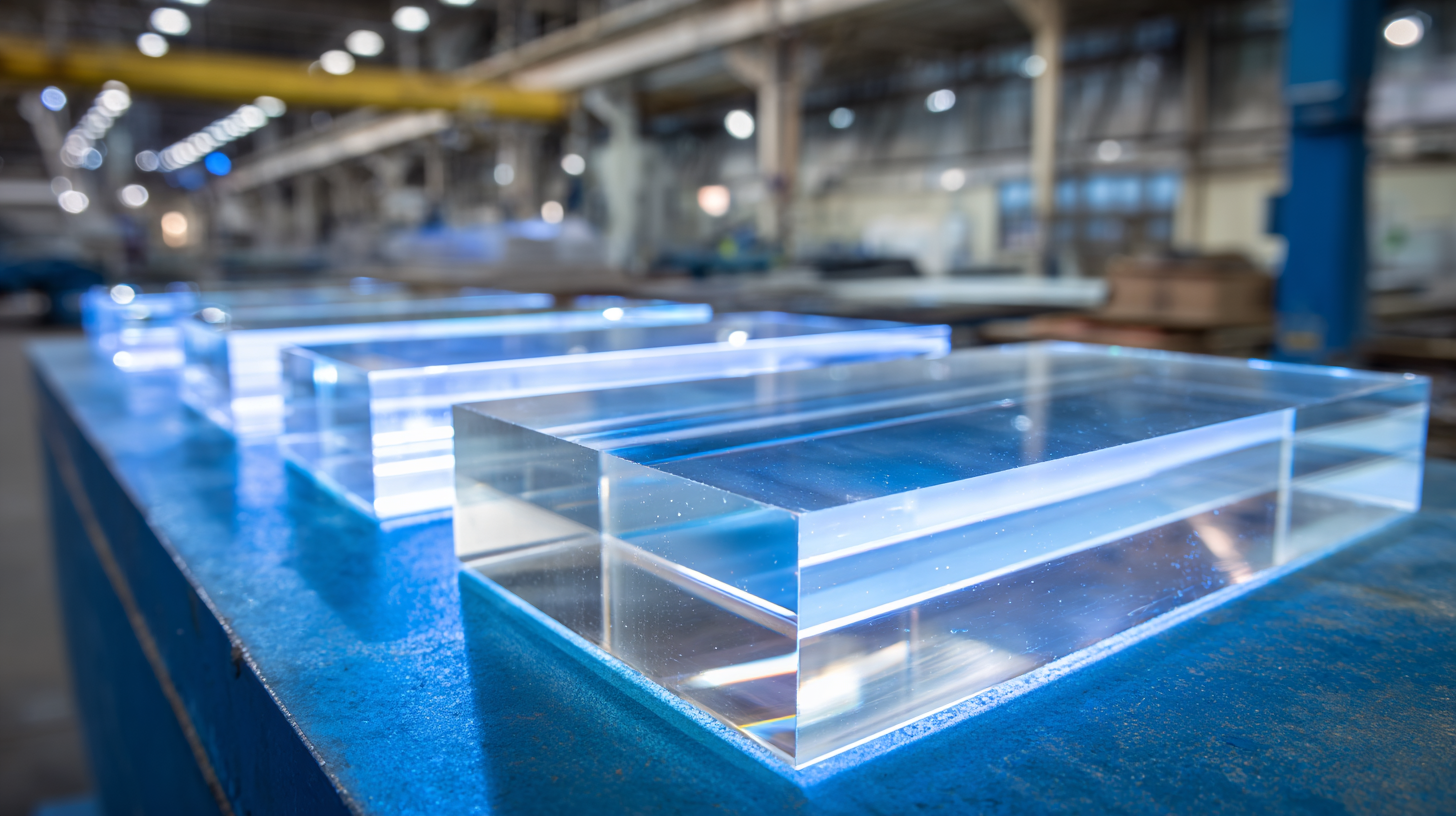

Acrylic, often known as polymethyl methacrylate (PMMA), has emerged as a favored material in fabrication due to its versatility, durability, and aesthetic appeal. According to a 2022 market analysis report by Grand View Research, the global acrylic market is projected to reach USD 10.1 billion by 2025, driven by its increasing use in industries such as signage, automotive, and construction. Acrylic's lightweight nature compared to glass, combined with its optical clarity and weather resistance, makes it an ideal choice for both functional and decorative applications.

In 2023, understanding the benefits of acrylic becomes essential for successful fabrication. Its ease of processing—whether through laser cutting, machining, or thermoforming—allows for greater design flexibility, enabling manufacturers to create intricate shapes and structures that cater to specific customer needs. Additionally, the material's high impact resistance (up to 10 times that of glass) ensures longevity and safety, which is particularly crucial in environments where durability is paramount. As the demand for customizable solutions grows, leveraging acrylic's properties will be vital for businesses aiming to stay competitive in a rapidly evolving market.

10 Essential Tips for Acrylic Fabrication Success in 2023

| Tip | Description | Benefit | Industry Insight |

|---|---|---|---|

| 1. Material Selection | Choose high-quality acrylic sheets to ensure durability. | Increases product lifespan and customer satisfaction. | Top manufacturers emphasize quality for better outcomes. |

| 2. Proper Cutting Techniques | Use specialized tools for smooth edges. | Reduces the need for additional finishing work. | Precision cutting can enhance aesthetic value. |

| 3. Temperature Control | Maintain optimal temperatures when heating acrylic. | Prevents warping or bubbling of the material. | Keeping controls ensures consistent results. |

| 4. Use of Jigs and Fixtures | Implementing jigs for repetitive tasks. | Increases accuracy and efficiency in production. | Jigs can reduce material waste significantly. |

| 5. Finishing Processes | Incorporate polishing and flame polishing techniques. | Enhances clarity and appearance of the acrylic. | Finish quality can differentiate products in the market. |

| 6. Adhesives and Joining Methods | Use appropriate adhesives for acrylic bonding. | Ensures strong and invisible joints. | Industry trends favor solvent cement for bonding. |

| 7. CNC Machining | Utilize CNC machines for precision fabrication. | Boosts production speed and accuracy. | Automation is becoming essential in modern fabrication. |

| 8. Surface Protection | Apply protective films during fabrication. | Minimizes scratches and damage during handling. | Surface protection is vital in high-volume production. |

| 9. Quality Control Measures | Implement rigorous quality checks at every stage. | Ensures high-quality final products. | Data shows improved customer retention with quality assurance. |

| 10. Trends and Innovation | Stay updated on industry trends and new technologies. | Helps in keeping a competitive edge. | Innovation is crucial for sustainability and growth. |

Key Industry Trends Influencing Acrylic Fabrication Techniques and Processes

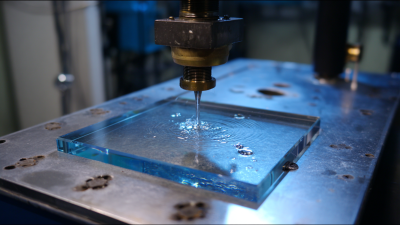

In 2023, the acrylic fabrication industry is experiencing significant shifts driven by key market trends. The rising demand for transparent materials in various sectors, including construction and automotive, is pushing manufacturers to adopt innovative fabrication techniques. Enhanced processing technologies, such as laser cutting and CNC machining, are becoming essential to achieve precision and efficiency, meeting the evolving needs of clients who prioritize both quality and sustainability in their projects.

Moreover, as the global plastic contract manufacturing market is poised to expand from USD 33.4 billion in 2025 to USD 48.9 billion by 2035, the integration of advanced materials and fabrication methods in acrylic production has never been more critical. Companies are increasingly focusing on sustainability, exploring environmentally friendly alternatives and recycling processes to reduce waste. This shift not only aligns with consumer preferences but also positions manufacturers favorably in a competitive market landscape, ensuring their growth and relevance in the years to come.

Essential Tools and Equipment for Efficient Acrylic Fabrication

Efficient acrylic fabrication requires a solid understanding of the essential tools and equipment that significantly enhance productivity and quality. In 2023, the focus has expanded beyond fundamental machinery to incorporate advanced auxiliary equipment, with the U.S. plastic processing auxiliary equipment market projected to grow at a CAGR of 3.2% from 2025 to 2030. This growth underscores the increasing demand for sophisticated tools that can streamline operations and improve output in acrylic fabrication.

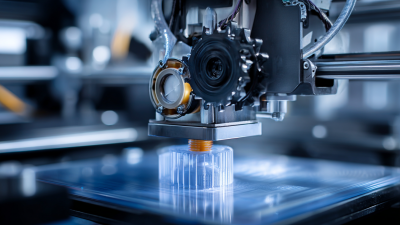

Key equipment includes precision saws for accurate cutting and CNC machines for intricate designs, both of which are vital for delivering high-quality finishes. Additionally, as the tools plastic market is anticipated to reach $2.92 billion by 2030, the importance of selecting materials that can withstand the rigors of fabrication cannot be overstated. The evolution of additive manufacturing also plays a significant role, offering innovative methods to create parts and minimize waste, ultimately leading to cost-saving practices in the production process. Investing in the right tools and keeping abreast of industry innovations can substantially enhance the efficiency and success of acrylic fabrication endeavors.

Best Practices for Maintaining Consistency and Quality in Acrylic Projects

When working with acrylic fabrication, maintaining consistency and quality is crucial for successful outcomes. One effective method to ensure uniformity is to implement standardized operating procedures for cutting, shaping, and finishing acrylic materials. By defining clear processes and utilizing templates or jigs, fabricators can reduce variability and enhance precision in their work. Regularly calibrating tools and equipment also plays an essential role in achieving consistent results, as even minor deviations can lead to significant discrepancies in finished products.

Moreover, quality control measures should be integrated throughout the fabrication process. This includes inspecting materials upon arrival for defects, as well as conducting routine checks during production. Implementing a feedback loop where team members can report issues and suggest improvements fosters a culture of quality and accountability. Training employees on the unique properties of acrylic and best practices for handling it is equally important; informed workers are more likely to produce work that meets established standards. By prioritizing these best practices, companies can significantly enhance the consistency and quality of their acrylic projects in 2023 and beyond.

Sustainability Considerations in Acrylic Fabrication: Why It Matters in 2023

In 2023, sustainability has emerged as a vital consideration in acrylic fabrication, reflecting a broader shift within the manufacturing industry towards eco-friendly practices. As consumers become increasingly aware of environmental issues, acrylic manufacturers must adapt by incorporating sustainable materials and efficient processes. The use of recycled acrylic and eco-friendly production techniques not only reduces waste but also meets the rising demand for sustainable products, helping businesses gain a competitive edge in the market.

Moreover, implementing sustainable practices within acrylic fabrication can lead to cost savings and improved brand reputation. Techniques such as reducing energy consumption during production and adopting water-efficient practices contribute to a lower carbon footprint. Additionally, the promotion of sustainability can resonate with environmentally conscious consumers, fostering brand loyalty. As the industry evolves, making sustainability a core aspect of acrylic manufacturing is not just beneficial for the planet; it's becoming essential for business viability in a competitive landscape.

Related Posts

-

The Art and Science of Acrylic Fabrication Techniques for Creative Projects

-

The Ultimate Guide to Choosing the Right Clear Plastic for Your Projects

-

Transform Your Space with Custom Cut to Size Acrylic Sheets for Every Project

-

Transform Your Space with Clear Acrylic Solutions for Modern Decor

-

Revolutionizing Product Design with Advanced Plastic Prototype Manufacturing Techniques

-

Exploring the Versatility of Cast Acrylic: Creative Applications for Modern Design