Posts

Top Benefits of Acrylic Sheets for Laser Cutting: Your Complete Guide

Acrylic sheets for laser cutting have become increasingly popular in various industries due to their versatility, durability, and aesthetic appeal. According to renowned expert in laser processing technology, Dr. Emily Carter, "The clarity and smooth finish of acrylic sheets make them an ideal choice for intricate laser cutting projects." This statement underscores the significance of acrylic sheets in enhancing both the functionality and visual impact of laser-cut designs.

In an era where precision and creativity are paramount, understanding the benefits of acrylic sheets for laser cutting can elevate your projects to new heights. These sheets not only allow for intricate designs but also offer a range of colors and thicknesses, making them suitable for applications in signage, displays, and custom artworks. As we delve deeper into the advantages and usage of acrylic sheets, it becomes clear why they are favored by professionals and hobbyists alike. Through this complete guide, we aim to explore the myriad benefits that acrylic sheets bring to the laser cutting industry, empowering creators to unlock their full potential.

Understanding Acrylic Sheets: Properties and Varieties

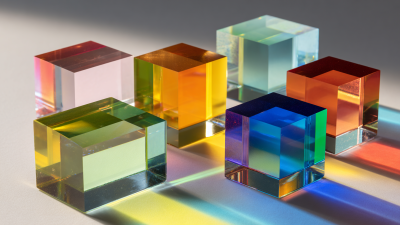

Acrylic sheets are widely recognized for their versatility and effectiveness in laser cutting applications. When considering their properties, acrylic stands out due to its outstanding clarity, which approaches that of glass, yet is significantly lighter and more durable. According to a report from the International Plastics Market Association, acrylic exhibits an impact resistance of up to 10 times greater than that of glass, making it a favored choice in industries requiring both aesthetics and strength. Additionally, acrylic sheets have a low moisture absorption rate, enhancing their stability in varying environmental conditions.

There are various types of acrylic sheets available, each suited to different applications. For instance, cast acrylic sheets are known for their superior optical clarity and are often used in displays and signage. On the other hand, extruded acrylic sheets offer excellent uniform thickness and are commonly preferred for applications requiring machining and bending. A study published by the Plastics Engineering Society highlights that extruded acrylic has a greater thermal stability compared to cast acrylic, making it suitable for more demanding applications. Understanding these properties and varieties can significantly aid manufacturers and designers in selecting the right material for their specific needs in laser cutting projects.

Advantages of Using Acrylic Sheets in Laser Cutting

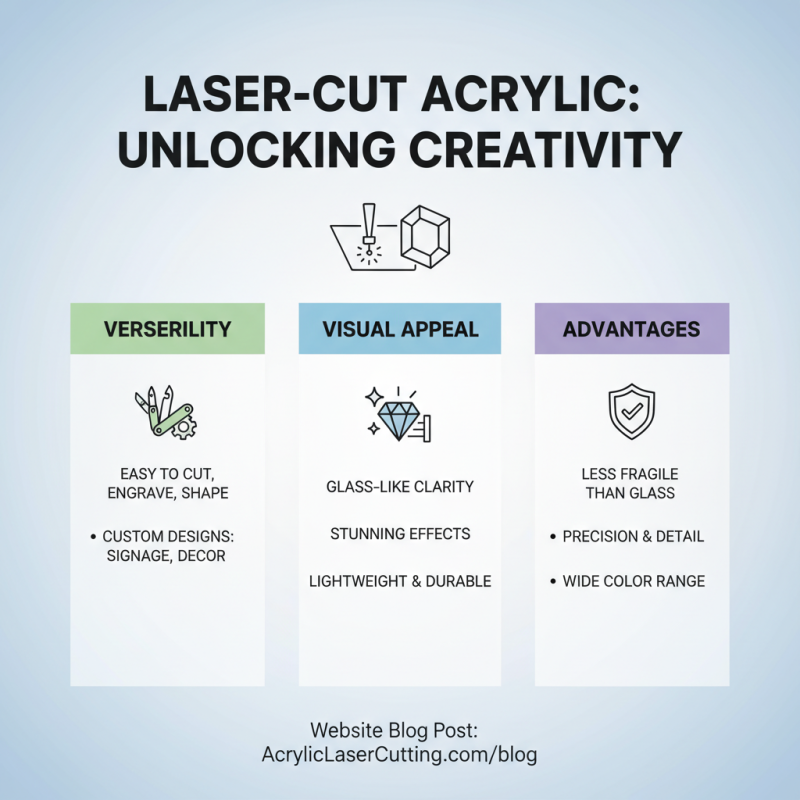

Acrylic sheets have become increasingly popular in laser cutting due to their unique properties that offer numerous advantages. One major benefit is their versatility in applications. Acrylic can be easily cut, engraved, and shaped into various designs, allowing for creativity and customization in projects ranging from signage to decorative elements. Its clarity and ability to mimic glass allow designers to achieve stunning visual effects without the weight and fragility of traditional glass materials.

Another significant advantage of using acrylic sheets in laser cutting is the precision they offer. The laser cutting process ensures clean edges and intricate designs, which can be challenging to achieve with other materials. This precision reduces the need for post-processing, saving time and resources. Additionally, acrylic sheets are available in a range of colors and finishes, enabling a broad spectrum of design choices that enhance the overall aesthetic of the final product. Overall, the benefits of acrylic sheets in laser cutting make them an ideal choice for both professional and hobbyist applications.

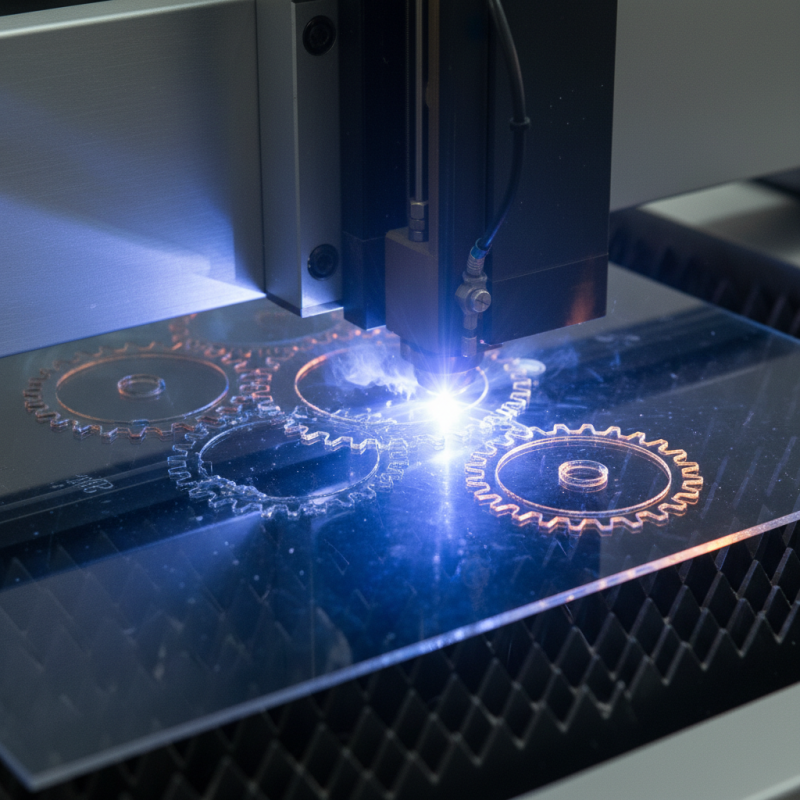

The Laser Cutting Process: Why Acrylic is Ideal

Acrylic sheets have gained popularity in the realm of laser cutting due to their unique properties that enhance the efficiency and quality of the process. The laser cutting technique employs a concentrated beam of light to precisely cut and shape materials, and acrylic's smooth surface allows for clean and intricate cuts. This optical clarity not only improves visibility during the cutting process but also ensures that the finished product retains a polished appearance, making it ideal for a variety of applications, from signage to decorative elements.

Another reason acrylic is preferred for laser cutting is its excellent durability and versatility. The material is lightweight yet strong, allowing for complex designs without fear of breakage. Additionally, acrylic sheets come in an array of colors and thicknesses, providing designers the flexibility to achieve diverse visual effects. During the laser cutting process, the material does not emit harmful fumes, making it a safer option for both operators and the environment. These characteristics make acrylic not only an ideal choice for laser cutting but also a favorite among designers seeking creative solutions.

Top Benefits of Acrylic Sheets for Laser Cutting

Applications of Laser-Cut Acrylic Sheets in Various Industries

The versatility of laser-cut acrylic sheets has positioned them as a preferred material across various industries. From signage and display making to architecture and product design, laser-cut acrylic provides a polished and professional finish that enhances visual appeal and functionality. In the advertising sector, companies utilize these sheets to create striking displays that attract customer attention, while in the interior design world, they are used for everything from decorative panels to lighting fixtures, allowing for intricate designs that are both practical and aesthetically pleasing.

In the art and crafts sector, laser-cut acrylic is increasingly popular among creatives. Artists often use these sheets for unique sculptures and installations, allowing for the precise execution of detailed designs that would be difficult to achieve through traditional methods. Additionally, the manufacturing industry leverages acrylic sheets for prototyping and producing custom components, as they are lightweight yet durable, making them suitable for various applications.

Tips: When working with laser-cut acrylic, consider the thickness you need based on your project requirements. Thicker sheets offer better durability for structural applications, whereas thinner sheets may be more suitable for intricate designs. Additionally, remember to prioritize safety by using protective gear during cutting and handling processes, ensuring a smooth and secure working environment.

Maintenance and Best Practices for Laser-Cut Acrylic Products

When working with laser-cut acrylic products, proper maintenance is essential to ensure longevity and quality. Acrylic sheets are not only visually appealing but also versatile in various applications, from signage to decorative items. Regular cleaning is crucial to maintain their clarity and shine. Use a mild soap solution with lukewarm water and a microfiber cloth to gently wipe the surface. Avoid abrasive materials, as they can scratch the acrylic, diminishing its appearance.

Another important aspect of maintaining acrylic products is proper storage. Keep them in a cool, dry place, away from direct sunlight to prevent warping and discoloration. If stacking sheets, use protective padding between them to avoid scratches. When assembling laser-cut pieces, consider using non-abrasive adhesives to ensure that your finished product remains in pristine condition.

**Tips**: To enhance the durability of your laser-cut acrylic items, consider applying a UV protective coating. Additionally, avoid exposing acrylic products to extreme temperatures, as rapid temperature changes can lead to cracking. Regularly inspect your items for any signs of wear or damage, addressing issues early to prolong their lifespan.

Top Benefits of Acrylic Sheets for Laser Cutting

| Benefit | Description | Maintenance Tips | Best Practices |

|---|---|---|---|

| Lightweight | Acrylic sheets are significantly lighter than glass, making them easier to handle and install. | Regularly clean with a soft cloth to avoid scratches. | Use protective film during transportation and avoid sharp objects. |

| Impact Resistant | Acrylic is much more durable than glass and can withstand various impacts. | Inspect periodically for signs of stress or damage. | Store sheets flat to prevent warping. |

| Versatile Applications | Can be used in signage, displays, and home decor due to its versatile nature. | Keep away from direct sunlight to prevent discoloration. | Choose the right thickness for your application needs. |

| Easy to Fabricate | Acrylic can be easily cut, drilled, and shaped using laser cutting technology. | Ensure equipment is calibrated correctly to maintain edge quality. | Conduct tests on scrap pieces before final cuts. |

| UV Resistant | Acrylic sheets can be made with UV stabilizers to resist fading in sunlight. | Regular cleaning with a non-abrasive cleaner can extend life. | Consider using UV-resistant coatings for added protection. |

Related Posts

-

Exploring the Versatility of Cast Acrylic: Creative Applications for Modern Design

-

Transform Your Space with Custom Cut to Size Acrylic Sheets for Every Project

-

Top 10 Acrylic Plastic Sheets for Your DIY Projects and Home Improvements

-

10 Essential Tips for Acrylic Fabrication Success in 2023 Based on Industry Data

-

The Miracle of Cast Acrylic Unveiling Its Versatile Applications in Modern Design

-

Transform Your Space with Clear Acrylic Solutions for Modern Decor