Posts

Top 10 Benefits of Plastic Molding for Your Manufacturing Needs

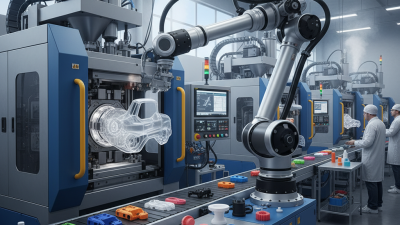

In the ever-evolving landscape of manufacturing, plastic molding has emerged as a pivotal technique, offering a multitude of advantages that cater to diverse industrial needs. According to a recent report by the Plastics Industry Association, the U.S. plastics industry is projected to reach $500 billion by 2025, highlighting the growing importance of efficient production methods like plastic molding. This process not only streamlines manufacturing operations but also enhances the quality and precision of the produced components.

As noted by Dr. Emily Tsai, a leading expert in the field of polymer engineering, "The versatility and cost-effectiveness of plastic molding make it an indispensable tool for modern manufacturers." Her insights underscore the excellent durability and design flexibility that come with plastic molding, which allow companies to innovate while managing production costs effectively. As businesses increasingly turn to this reliable manufacturing solution, understanding its myriad benefits has never been more crucial for achieving competitive advantage in today’s fast-paced market.

Overview of Plastic Molding in Manufacturing Processes

Plastic molding is a pivotal technique employed in contemporary manufacturing processes, significantly influencing production efficiency and design flexibility. This method encompasses various techniques, including injection molding, blow molding, and rotational molding, each offering unique advantages for diverse applications. According to a report from the Plastics Industry Association, the U.S. plastics industry employs around 1 million workers and contributes over $400 billion annually to the economy, emphasizing the critical role of plastic molding in manufacturing practices.

The versatility of plastic molding allows manufacturers to produce complex shapes and designs that would be challenging or impossible with traditional materials. Injection molding, for instance, can produce thousands of identical parts quickly, reducing costs and time-to-market. A study by Grand View Research estimates that the global injection molding market will reach $300 billion by 2025, driven by the increasing demand for lightweight materials in various sectors such as automotive and consumer goods. Furthermore, the process minimizes waste by allowing for precise material usage, making it an environmentally favorable option compared to other manufacturing methods.

In addition to cost-effectiveness and efficiency, plastic molding supports innovation in product design. With advancements in polymer technology, manufacturers can explore new applications that were previously not feasible, thereby fueling growth in various industries. A report from Mordor Intelligence indicates that the demand for plastic molding products is expected to grow by over 6% annually, further highlighting its importance in future manufacturing standards.

Cost Efficiency: How Plastic Molding Reduces Production Expenses

Plastic molding has become a cornerstone of manufacturing due to its remarkable cost efficiency. Industry studies have shown that using plastic molding can reduce production costs by as much as 30% compared to traditional manufacturing processes. This reduction in expenses is primarily achieved through lower material costs, decreased waste, and shorter production times.

For example, thermoplastics, which are commonly used in plastic molding, can be produced at a fraction of the cost of metals while offering comparable durability and strength.

Moreover, the ability to produce complex parts with high precision in one mold also minimizes the number of secondary operations needed, further driving down costs. According to a report from MarketsandMarkets, the global injection molding market is expected to reach $346 billion by 2025, highlighting the growing demand for efficient manufacturing solutions.

This trend indicates not only a preference for cost-effective strategies but also the increasing reliance on versatile plastic molding methods that can adapt to various production scales and needs.

Design Versatility: Customization Options in Plastic Molding

Plastic molding offers a remarkable level of design versatility, making it an essential component for manufacturers looking to customize their products. With techniques like injection molding and blow molding, companies can create intricate shapes and designs that are often unattainable with other materials. This adaptability facilitates the production of a wide array of products, from simple household items to complex industrial components, allowing manufacturers to meet specific customer needs while maintaining efficiency.

When considering plastic molding, it's essential to explore the various customization options available. Manufacturers can not only choose from an extensive range of materials but can also fine-tune the physical characteristics such as color, texture, and rigidity. This level of customization enhances the aesthetic appeal of products and can lead to improved functionality.

**Tip:** To maximize the benefits of plastic molding, collaborate closely with your design team from the outset. Early involvement will help identify potential design changes that can reduce costs and streamline production.

Another important factor to consider is the scalability of plastic molding processes. The same molds can be utilized for both small-batch and large-scale productions, adapting to fluctuations in demand without sacrificing quality.

**Tip:** Keep in mind that investing in high-quality molds can lead to longer production runs, reducing per-unit costs over time. Proper maintenance of these molds can further enhance their lifespan, ensuring that your customization efforts yield long-term benefits.

Enhanced Production Speed: Benefits of Rapid Plastic Molding Techniques

Rapid plastic molding techniques significantly enhance the production speed for manufacturers, allowing them to meet the demands of a fast-paced market. By implementing advanced processes such as injection molding or blow molding, manufacturers can produce high volumes of components in a fraction of the time compared to traditional methods. This efficiency not only accelerates the production cycle but also streamlines the ability to scale operations in response to fluctuating market needs.

Moreover, rapid plastic molding minimizes lead times by reducing the time required for tooling and setup. This results in a faster time-to-market for new products, giving manufacturers a competitive edge. The ability to quickly iterate designs and adjust production parameters allows for more effective testing and refinement before full-scale production, leading to higher quality end products. Ultimately, enhanced production speed through rapid plastic molding techniques plays a crucial role in optimizing manufacturing efficiency and responsiveness in an increasingly dynamic industrial landscape.

Top 10 Benefits of Plastic Molding for Your Manufacturing Needs

Sustainability Considerations: Eco-Friendly Aspects of Plastic Molding

The increasing emphasis on sustainability within the manufacturing sector has brought plastic molding into the spotlight as a more eco-friendly production method. One of the primary advantages of plastic molding is its potential for resource efficiency. The process typically generates less waste compared to traditional manufacturing methods, which often involve cutting or machining materials down from larger blocks. By utilizing precise techniques such as injection molding or blow molding, manufacturers can create complex shapes with minimal excess material, thereby reducing the overall environmental impact.

Furthermore, advancements in plastic technology have led to the development of biodegradable and recyclable materials that can be used in plastic molding. This shift not only helps in mitigating waste but also promotes a circular economy where materials are repurposed rather than discarded. Eco-conscious manufacturers are increasingly adopting these innovative materials to align with sustainability goals and meet the growing consumer demand for environmentally friendly products. By choosing plastic molding, businesses are not only enhancing their operational efficiency but also contributing positively to environmental conservation efforts.

Related Posts

-

10 Best Plastic Injection Techniques for Optimal Manufacturing Efficiency

-

Top 5 Uses of Clear Plastic in Modern Industries: Insights & Trends

-

Transform Your Space with Custom Cut to Size Acrylic Sheets for Every Project

-

Why Clear Plastic is the Perfect Choice for Your Packaging Needs

-

Why Plastic Prototype Manufacturing is Essential for Successful Product Development

-

Top 10 Acrylic Plastic Sheets for Your DIY Projects and Home Improvements