Posts

2026 How to Find the Best Injection Molding in Las Vegas?

In the bustling city of Las Vegas, finding the best injection molding services can be challenging. Expert Jamie Lewis, a leading figure in the injection molding Las Vegas industry, emphasizes, "Quality materials and skilled craftsmen are key to great products." This highlights the importance of selecting a provider who prioritizes both quality and expertise.

When searching for injection molding Las Vegas options, consider factors like experience and customer reviews. Many companies may boast impressive machinery but may lack in communication or timely delivery. Potential clients should ask for samples and references to gauge the reliability of the services.

The landscape of injection molding Las Vegas is diverse, with various companies vying for attention. It is essential to reflect on your specific needs. Do they align with what the company offers? Many clients overlook this vital aspect, leading to dissatisfaction. Making an informed choice can save time and money in the long run.

Understanding Injection Molding: A Key to Effective Production Processes

Injection molding plays a crucial role in modern manufacturing. It allows for high-volume production of complex parts. Understanding this process is vital for effective production. This technique involves injecting molten material into a mold, where it cools and solidifies. Different materials can be used, including plastics and metals. Variations in temperature and pressure can lead to varying results.

When selecting an injection molding service in Las Vegas, it's essential to consider their expertise. Not all companies have the same level of skill. Some may rush production, leading to defects. Others might use outdated techniques. Assessing their quality control measures is important. You want a partner who values precision and consistency. Communication is key. Discuss your needs clearly to avoid misunderstandings.

One challenge in this sector is keeping pace with technological advancements. Machinery constantly evolves. If a company does not invest in upgrades, quality may suffer. Regular evaluations of the production process can highlight areas for improvement. Feedback from design teams is also invaluable. Using this input can refine the process, enhancing product quality.

Evaluating Injection Molding Companies: Criteria for Selection

When searching for the best injection molding companies in Las Vegas, consider a few key criteria. Start with their experience in the industry. Companies with a robust portfolio can often deliver higher quality results. Look for specialized expertise that aligns with your project needs. This can make a significant difference in production efficiency.

Next, evaluate their technology and equipment. Advanced machinery can increase precision and reduce waste. You might also want to ask about their quality control processes. Consistent testing ensures that the final products meet your specifications. Inquire about their materials. A range of material options can lead to better product customization.

Don’t forget to read customer reviews. Satisfied clients share valuable insights. However, a few negative reviews might indicate areas to reflect on. Communication is crucial. Companies that prioritize transparency and responsiveness may enhance your project experience. Remember, the best choice isn’t just about cost; it's about value and reliability.

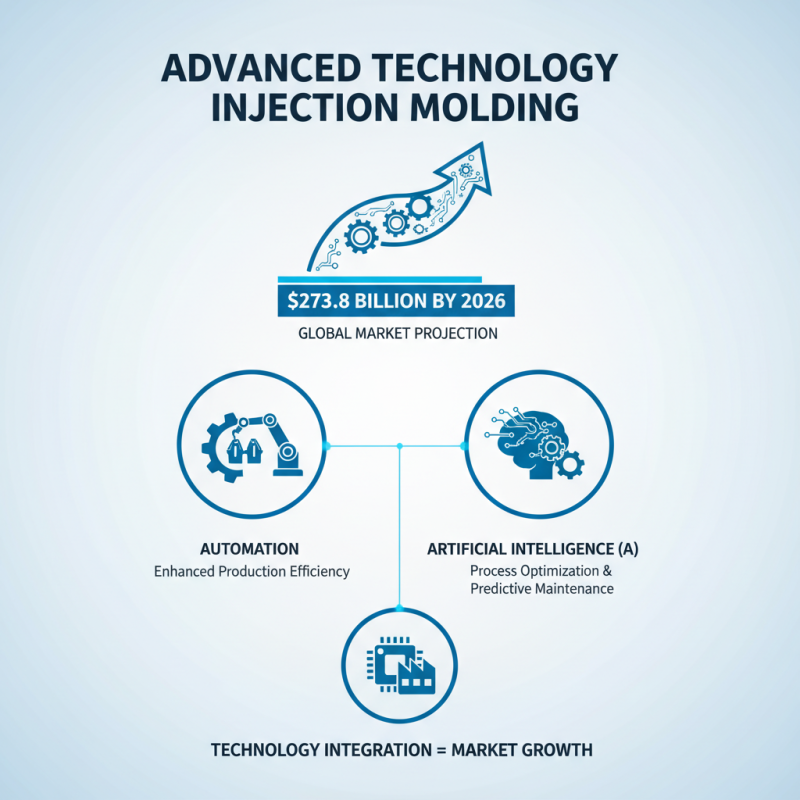

The Role of Advanced Technology in Injection Molding Quality

The role of advanced technology in injection molding is significant. According to a report by MarketsandMarkets, the injection molding market is projected to reach $273.8 billion by 2026. This growth is fueled by the integration of advanced technologies. Automation and AI play key roles in enhancing production efficiency.

3D printing revolutionizes mold design. It allows for rapid prototyping and reduces lead times. Studies show that companies using smart manufacturing can reduce their cycle time by up to 50%. However, the implementation can be challenging. Many manufacturers struggle with adapting to these new technologies effectively.

Quality control is another area where technology shines. Real-time monitoring systems can detect issues early. A slight temperature variation can lead to defects in parts. Advanced sensors help mitigate this risk. Still, many businesses overlook the importance of regular training in these technologies. The gap in skills can hinder their full potential. Investing in continual learning is essential for maintaining competitive quality standards.

Cost Analysis of Injection Molding Services in Las Vegas

When considering injection molding services in Las Vegas, cost analysis is crucial. Prices can vary significantly based on several factors. For example, material choice greatly impacts the overall expense. Some materials are more affordable, while others add to the project's cost. Labor fees should also be considered. Highly skilled workers may charge more, but they often lead to better results.

It is important to gather quotes from different providers. You may find discrepancies in pricing even for similar projects. Sometimes, the cheapest option may not provide the best quality. Be cautious of hidden fees as they can inflate the final bill. Analyze the entire process, from design to production, to ensure your budget aligns with your needs.

Understanding these costs will require reflection on your project goals. Are you looking for speed, quality, or affordability? Sometimes you may need to compromise. Balancing these elements can be challenging and may lead to unexpected issues. Keep an open mind during this process.

Cost Analysis of Injection Molding Services in Las Vegas (2026)

Assessing Customer Reviews and Industry Reputation for Molding Providers

When searching for the best injection molding services in Las Vegas, customer reviews play a crucial role. Many potential clients often overlook this aspect. Reviews can reveal insights about a provider's reliability and service quality. Check online platforms where clients share their experiences. Pay attention to both positive and negative feedback. This balance offers a clearer picture.

Tips: Consider looking for detailed comments. Specific experiences can highlight strengths or weaknesses. Also, note the frequency of certain complaints. If multiple reviews mention similar issues, it may signal a problem.

Industry reputation also matters. Research how long providers have been in business. Experience often correlates with quality. However, newer companies might offer innovative solutions. Don’t dismiss them hastily. Investigating their achievements can provide valuable insights.

Tips: Ask for case studies or past projects. This can reveal whether they meet your requirements. Be wary of overly positive reviews. Genuine feedback often includes some critique. Embrace reviews as a tool, not an absolute measure.

2026 How to Find the Best Injection Molding in Las Vegas?

| Service Provider | Customer Rating (1-5) | Industry Reputation (1-5) | Years in Business | Specialties |

|---|---|---|---|---|

| Provider A | 4.5 | 4.8 | 10 | Automotive, Consumer Products |

| Provider B | 4.2 | 4.5 | 8 | Medical, Electronics |

| Provider C | 3.9 | 4.2 | 5 | Packaging, Toys |

| Provider D | 4.7 | 4.9 | 12 | Home Appliances, Furniture |

| Provider E | 4.0 | 4.3 | 15 | Industrial, Aerospace |

Related Posts

-

Top 10 Benefits of Plastic Molding for Your Manufacturing Needs

-

What is a plastic molding machine and how does it work?

-

10 Essential Tips for Acrylic Fabrication Success in 2023 Based on Industry Data

-

Top Benefits of Acrylic Sheets for Laser Cutting: Your Complete Guide

-

2025 Top Cast Acrylic Uses Benefits and Applications You Need to Know

-

Transform Your Space with Custom Cut to Size Acrylic Sheets for Every Project