Posts

10 Best Plastic Injection Techniques for Optimal Manufacturing Efficiency

Plastic injection has become a cornerstone technique in the manufacturing industry, revolutionizing the way various products are produced from complex components to simple everyday items. As manufacturers continuously strive for increased efficiency and cost-effectiveness, understanding the diverse plastic injection techniques available is crucial. These methods not only enhance product quality but also optimize production speed and reduce waste, contributing to a more sustainable manufacturing environment.

In this article, we will explore the ten best plastic injection techniques that can significantly improve manufacturing efficiency. Each technique offers unique benefits and applications, enabling manufacturers to select the most suitable approach for their production needs. By leveraging these innovative strategies, companies can maximize their production capabilities, decrease operational costs, and ultimately gain a competitive edge in the market. Whether you are new to plastic injection or looking to refine your current practices, these insights will help you harness the full potential of this versatile manufacturing process.

10 Essential Plastic Injection Techniques for Streamlining Production

Streamlining production in plastic injection molding is essential for enhancing efficiency and reducing costs. One effective technique is optimizing the injection molding process parameters, which include temperature, pressure, and cycle time. Properly adjusting these factors can minimize defects and maximize output, leading to a more streamlined operation.

Tips: Utilize simulation software to predict the outcomes of different parameter settings in the design phase. This can help identify the most efficient combinations, saving time and resources.

Another crucial technique is the implementation of automated systems for material handling and part inspection. Automation not only accelerates the production process but also reduces the likelihood of human error, ensuring consistent quality in the final products.

Tips: Invest in robotic solutions that can handle repetitive tasks, thereby freeing up skilled workers to focus on more complex operations. This transition enhances productivity and allows for quicker adjustments to production lines as needed.

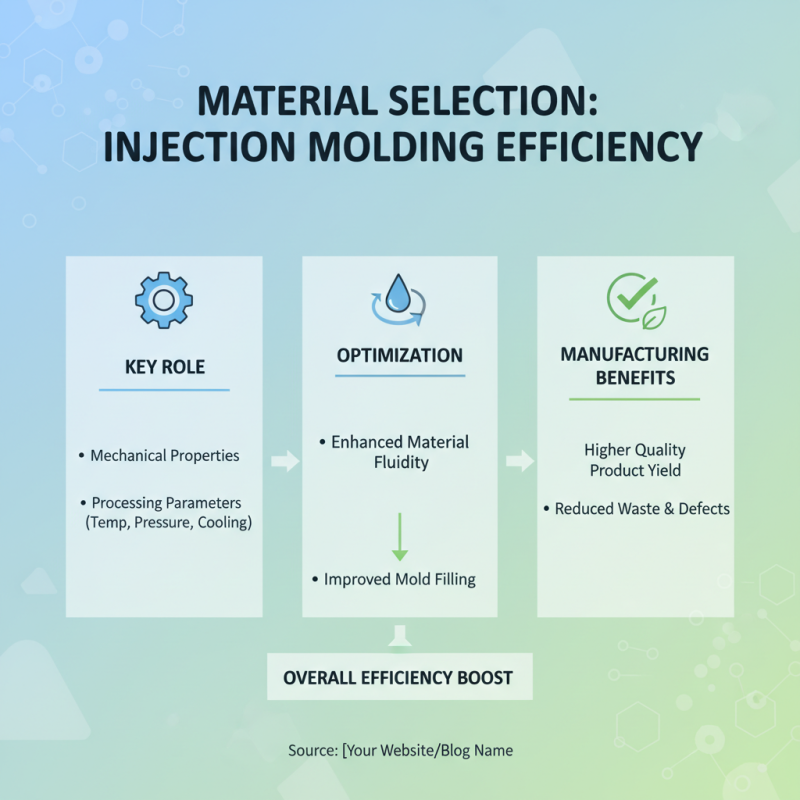

Understanding the Role of Material Selection in Injection Molding Efficiency

Material selection plays a pivotal role in the efficiency of injection molding processes. The choice of material influences not only the mechanical properties of the final product but also affects the processing parameters such as temperature, pressure, and cooling times. By selecting the appropriate resin, manufacturers can enhance the fluidity of the material during the injection phase, resulting in better mold filling and reducing the occurrence of defects. This ensures a higher yield of quality products and minimizes waste, both of which contribute to overall manufacturing efficiency.

Additionally, understanding the interactions between different materials and injection molding techniques can lead to more informed decisions during product design and development. For instance, lightweight thermoplastics might be favored for complex geometries to optimize cycle times, while reinforced materials may be chosen for applications requiring enhanced strength and durability. By aligning material characteristics with the specific requirements of the injection molding process, manufacturers can achieve not only cost savings but also improved performance in the end-use applications of their products. Such strategic material selection is essential for maintaining competitiveness in an ever-evolving manufacturing landscape.

The Impact of Cycle Time on Manufacturing Productivity in Injection Molding

Cycle time is a critical factor in the efficiency of injection molding, directly impacting the overall productivity of manufacturing processes. In injection molding, the cycle time encompasses the time required for the entire molding process, including injection, cooling, and ejection of the molded part. A shorter cycle time allows manufacturers to produce more parts in less time, which can significantly enhance throughput and reduce labor costs. On the other hand, excessively long cycle times can lead to bottlenecks in production, increased operational expenses, and a lower return on investment.

To optimize cycle time, manufacturers often adopt various strategies, including modifying the design of molds, employing advanced materials, and utilizing state-of-the-art machinery equipped with faster response times. Additionally, streamlining the cooling phase—often the most time-consuming part of the molding cycle—can lead to substantial improvements in efficiency. Techniques such as the use of conformal cooling channels can help achieve uniform temperature distribution, thereby decreasing the cooling time. By continually analyzing and refining the injection molding process, manufacturers can significantly boost their productivity and maintain a competitive edge in the marketplace.

Leveraging Automation in Plastic Injection for Enhanced Operational Efficiency

The integration of automation in plastic injection molding has become a pivotal strategy for enhancing operational efficiency across manufacturing sectors. According to a 2022 report by the Automation World Research, approximately 67% of manufacturers have adopted some form of automation, recognizing its potential to streamline production processes and reduce labor costs. Automation technologies, such as robotic arms and injection molding machines equipped with advanced sensors, are facilitating quicker cycle times and more precise control over the molding process. This shift not only minimizes human error but also optimizes resource allocation, enabling companies to achieve higher output rates without compromising quality.

Moreover, data from the International Society of Automation indicates that companies employing automated systems in their injection molding operations have seen an increase in throughput by up to 30%. By leveraging automation tools, manufacturers can continuously monitor and adjust parameters in real-time, leading to reduced waste and improved material efficiency. The implementation of predictive maintenance solutions, as suggested in the 2021 Manufacturing Trends Report, is also on the rise, further contributing to reduced downtime and enhanced productivity. With the ongoing advancements in automation technology, businesses in the plastic injection molding industry are well-positioned to achieve significant gains in operational efficiency and competitiveness.

10 Best Plastic Injection Techniques for Optimal Manufacturing Efficiency

This chart displays the efficiency ratings of various plastic injection techniques, showcasing how automation enhances operational performance.

Evaluating the Latest Innovations in Injection Molding Technology and Methods

Recent advancements in injection molding technology are significantly influencing manufacturing efficiency across various industries. For instance, the introduction of smarter mold designs and automation is streamlining the production process. According to a report by the International Society of Plastics Engineers, the adoption of advanced sensors and AI-driven analytics has been shown to improve cycle times by up to 30%, allowing for a more responsive production environment that meets increasing market demands.

Moreover, innovations such as multi-material injection molding and 3D printing integration are enabling manufacturers to produce more complex parts with precision. A study by Market Research Future indicates that the global injection molding market is expected to reach $396 billion by 2024, with a compound annual growth rate (CAGR) of 5.3%. Such growth is attributed to enhanced flexibility in design capabilities and reduced waste generation through these innovative processes. The focus on efficiency is driving companies to invest in sustainable practices, further optimizing production while addressing environmental concerns.

10 Best Plastic Injection Techniques for Optimal Manufacturing Efficiency

| Technique | Description | Advantages | Applications |

|---|---|---|---|

| Multi-Cavity Molding | Uses multiple cavities in a single mold to produce several parts simultaneously. | Increased production efficiency and reduced cycle time. | Consumer goods, packaging. |

| Gas-Assisted Injection Molding | Utilizes gas to create hollow sections within molded parts. | Reduces weight and material usage. | Automotive parts, large housings. |

| Insert Molding | Integrates metal or other inserts into molded parts during the injection process. | Enhances strength and functionality of parts. | Electronics, automotive components. |

| Overmolding | Applies a second layer of material over a previously molded part. | Improves grip, aesthetics, and sealing. | Consumer products, medical devices. |

| Liquid Silicone Rubber (LSR) Injection Molding | Involves injecting silicone rubber into a mold at high temperatures. | Excellent thermal stability and durability. | Medical, automotive, consumer goods. |

| Additive Manufacturing Integration | Combines traditional injection molding with 3D printing techniques. | Flexibility in design and production runs. | Prototyping, custom components. |

| Bioplastics Injection Molding | Uses biodegradable plastics for eco-friendly manufacturing. | Sustainable and environmentally friendly products. | Packaging, disposable items. |

| Hot Runner Systems | Maintains the melt temperature of the plastic to reduce cycle time. | Minimizes waste and improves efficiency. | Complex and high-volume parts. |

| Advanced Simulation Technologies | Utilizes simulation software to optimize the injection process. | Reduces errors and enhances design quality. | Part design and molding process optimization. |

| Smart Injection Molding Machines | Equipped with IoT capabilities for real-time monitoring and data management. | Enhances production control and efficiency. | All manufacturing processes requiring real-time oversight. |

Related Posts

-

How to Choose the Perfect Acrylic Sheets for Your Project

-

Exploring the Versatility of Clear Plastic Sheets: 10 Innovative Applications Backed by Industry Insights

-

Top 5 Benefits of Using Plexiglass Sheets Cut to Size for Your Projects

-

Top 5 Uses of Clear Plastic in Modern Industries: Insights & Trends

-

2025 Top 5 Colored Acrylic Sheets for Creative Projects and Designs

-

Top 10 Tips for Choosing the Best Plastic Board for Your Projects