Posts

How to Choose the Best Plastic Injection Molding Process for Your Project

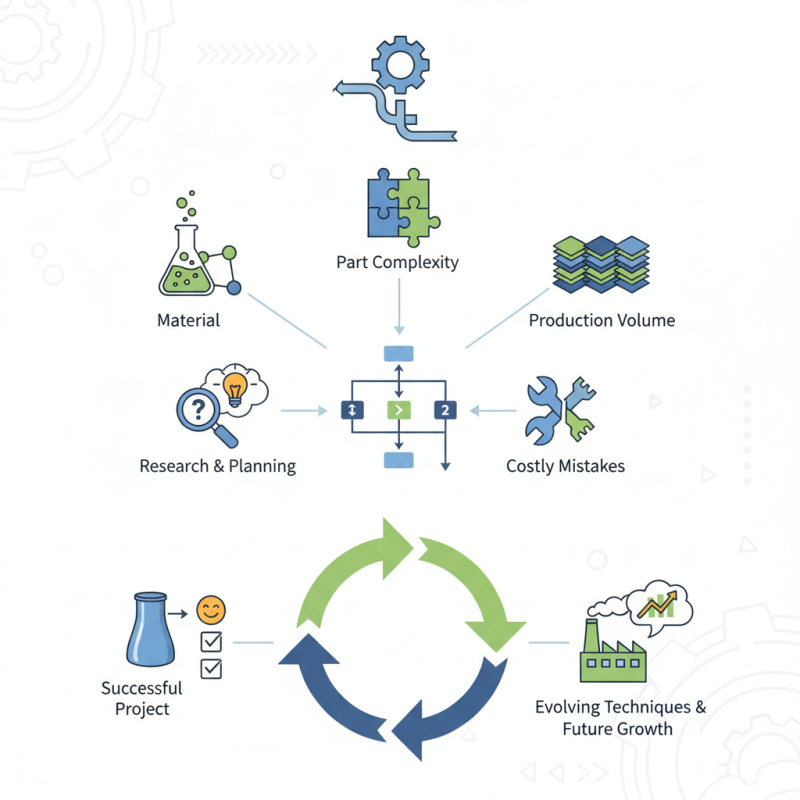

Choosing the right method for plastic injection is crucial for project success. Plastic injection molding offers consistent quality and efficiency. However, not all projects are the same. Each requires a tailored approach.

Different factors influence the best plastic injection method. These include material, part complexity, and production volume. Selecting the wrong process can lead to costly mistakes. Many projects struggle due to improper planning or understanding of plastic capabilities.

As the industry evolves, new techniques emerge. Staying informed is essential for making the best choice. Reflect on your project's goals, and consider how the chosen process aligns with them. Inadequate research can lead to regrets down the line. Make thoughtful decisions to avoid pitfalls in your plastic injection journey.

Understanding Plastic Injection Molding: Key Concepts and Applications

Plastic injection molding is a widely used manufacturing process. It involves injecting molten plastic into a mold. This method is popular because it produces complex shapes and high precision components. Understanding the basics is crucial for anyone considering this process.

Key concepts include cycle time, mold design, and material selection. Cycle time refers to how quickly a part can be produced. A shorter cycle time saves time, but can affect quality. Mold design impacts the efficiency and durability of the process. Poorly designed molds can lead to defects.

Applications for plastic injection molding are diverse. From automotive parts to household items, the possibilities are vast. However, considering the environmental impact is essential. Plastic waste is a growing concern. Not all projects prioritize sustainability, which can lead to bigger issues down the line.

Identifying Your Project Requirements: Material, Design, and Functionality

Choosing the right plastic injection molding process starts with understanding your project requirements. Material selection is crucial. Different plastics offer various strengths, flexibility, and durability. For instance, ABS is tough yet lightweight, while polycarbonate is known for its high impact resistance. Consider the environment where the product will be used.

Design is another essential factor. Complexity often increases the cost and time for production. A simple design might be easier to produce but may not always meet functional requirements. For example, intricate designs could provide better functionality but might lead to challenges in the molding process. Reflect on the goals for your product. Will it be aesthetic, functional, or both?

Functionality cannot be overlooked. Will your product be subjected to high stress? What about exposure to chemicals? Specify these aspects clearly during the planning phase. If the requirements change, revisit the material and design choices. Be open to adjustments. Sometimes, re-evaluating your project can lead to better outcomes. A more efficient process might emerge from a clearer understanding of what you truly need.

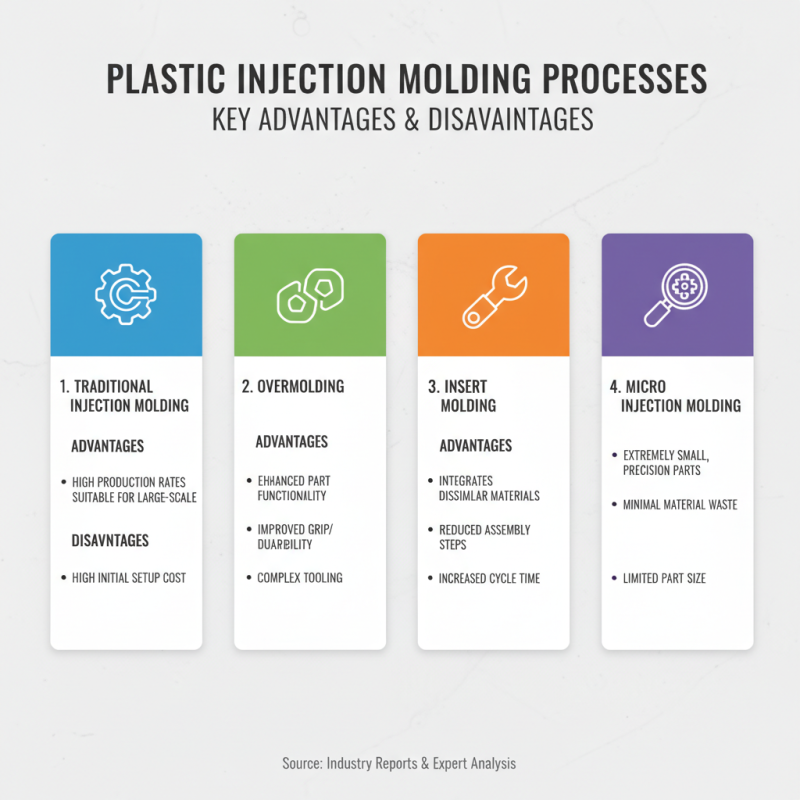

Evaluating Different Injection Molding Processes: Pros and Cons

Choosing the right plastic injection molding process can be daunting. Each method presents unique advantages and drawbacks. For instance, traditional injection molding is widely used due to its efficiency. It offers high production rates, making it suitable for large-scale projects. However, the initial setup cost can be significant.

On the other hand, processes like micro-injection molding have gained popularity for producing small, intricate parts. This method requires precision but can be slow, making it less ideal for mass production. Another option is the gas-assisted injection molding, which reduces the amount of plastic needed. It creates lighter parts but might not be suitable for all designs.

Evaluating these options requires careful consideration. Manufacturers should weigh their project needs against each process's limitations. Sometimes, a hybrid approach may provide the best results. It’s crucial to reflect on the end goal and expected outcomes. The right choice hinges on factors beyond just cost, emphasizing the importance of a tailored approach.

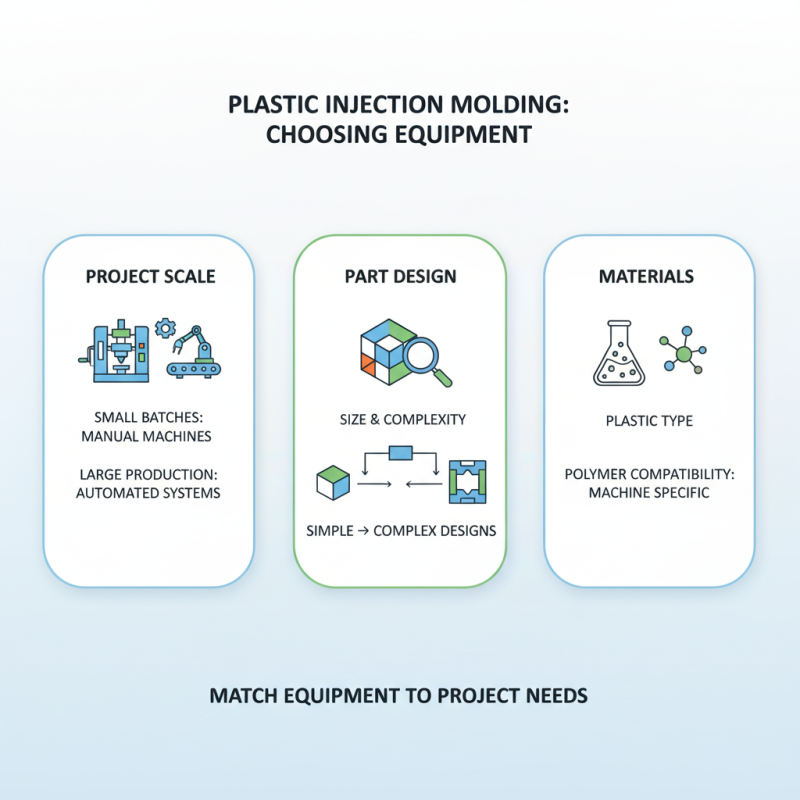

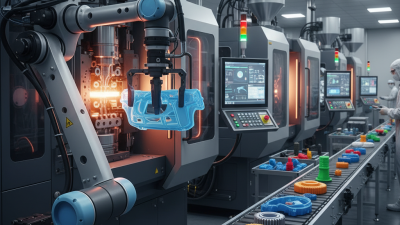

Selecting the Right Equipment and Technology for Your Needs

Choosing the right equipment for plastic injection molding is crucial. The type of project determines the machinery needed. For small-scale production, a simple, manual machine may suffice. Larger projects may require fully automated systems. Consider the size and complexity of your designs. Materials matter too. Some machines handle certain plastics better than others.

When evaluating technology, think about energy efficiency and speed. Some machines are faster but consume more energy. This could impact your budget in the long run. Look for models that balance efficiency and production needs. Engaging with various suppliers can provide insights into their offerings. Yet, remember that each solution has limitations.

Ask yourself: Which features are essential? Are you ready to compromise on some aspects? Sometimes, the latest technology may not suit your specific requirements. Reflect on past projects to guide your current choices. Understanding your goals will steer you towards the best decision.

Cost Considerations: Budgeting for Plastic Injection Molding Projects

When budgeting for plastic injection molding projects, several factors come into play. The average cost of injection molding can range from $5,000 to over $100,000, depending on project complexity. According to industry reports, the tooling cost is typically a significant portion. Design errors can inflate this cost. For instance, a poorly designed mold might need revisions, leading to additional expenses.

Material selection also affects your budget. The choice of resin impacts overall costs dramatically. For example, commodity plastics are cheaper than engineering-grade materials. It's essential to balance quality and cost. Furthermore, workforce skill levels can influence production costs. Hiring more experienced technicians might seem costly, but their efficiency could save you money over time.

Production volume is another crucial element in budgeting. Lower volumes can lead to higher per-part costs. Scaling up reduces these costs significantly. However, what if demand declines? The initial investment may not yield expected returns. Reflecting on your project's scope, market needs, and future demand is vital. A well-thought-out budget can guide these decisions, but flexibility remains essential in this ever-evolving industry.

Cost Considerations for Plastic Injection Molding Projects

Related Posts

-

10 Best Plastic Injection Techniques for Optimal Manufacturing Efficiency

-

Mastering the Injection Molding Process: Tips for Streamlining Production Efficiency

-

How to Optimize Plastic Parts Manufacturing for Efficiency and Quality

-

Top 10 Benefits of Plastic Molding for Your Manufacturing Needs

-

Why Plastic Prototype Manufacturing is Essential for Successful Product Development

-

The Ultimate Guide to Choosing the Right Clear Plastic for Your Projects