Posts

Why is Plastic Fabrication Important for Modern Industries?

Plastic fabrication plays a vital role in modern industries. It encompasses various processes, such as cutting, bending, and assembling plastic materials. This versatility makes plastic an ideal choice for numerous applications. From automotive parts to medical devices, plastic fabrication is everywhere.

The importance of plastic fabrication is evident in its ability to meet specific demands. Industries often require customized solutions. This is where plastic fabrication shines. It allows for the creation of tailored products that satisfy unique needs. However, some challenges arise from this flexibility. Not all plastics are suitable for every application, leading to potential issues.

Moreover, sustainability concerns come into play. The environmental impact of plastic production is a topic of ongoing debate. Industries must reflect on their practices. Finding balance between innovation and ecological responsibility is crucial. As we advance, the role of plastic fabrication will continue to evolve, highlighting both its strengths and weaknesses in modern manufacturing.

The Role of Plastic Fabrication in Manufacturing Processes

Plastic fabrication plays a crucial role in modern manufacturing processes. It allows industries to create parts that are lightweight yet durable. This is especially important in automotive and aerospace sectors, where every ounce matters. The versatility of plastic means it can be molded into complex shapes for a variety of applications.

Tip: Always assess the project's requirements before choosing a plastic type. Different plastics have different properties and capabilities. Selecting the right material can improve durability and performance.

In many industries, the demand for custom parts grows daily. Plastic fabrication makes it easier to meet these needs. However, sometimes, the precision required is not achieved. This can lead to product rework, which wastes time and resources. Learning from these mistakes is vital for continuous improvement.

Tip: Regular training for staff can help reduce errors in fabrication processes. Well-trained workers make fewer mistakes and understand how to troubleshoot issues quickly. This can enhance overall efficiency.

Why is Plastic Fabrication Important for Modern Industries? - The Role of Plastic Fabrication in Manufacturing Processes

| Dimension | Description | Importance | Application Areas |

|---|---|---|---|

| Versatility | Plastic can be molded into various shapes and sizes. | Allows for customization in product design. | Automotive, Electronics, Consumer Goods |

| Cost-effectiveness | Lower material and production costs compared to metals. | Reduces overall manufacturing expenses. | Packaging, Toy Manufacturing, Medical Devices |

| Durability | Highly resistant to corrosion and impacts. | Increases the lifespan of products. | Construction, Aerospace, Industrial Equipment |

| Lightweight | Significantly lighter than traditional materials. | Improves efficiency in transportation and handling. | Logistics, Electronics, Sports Equipment |

| Eco-friendliness | Increasingly recyclable and bio-based options available. | Supports sustainable manufacturing practices. | Green Packaging, Renewable Energy, Biodegradable Products |

Advancements in Plastic Materials for Industry Applications

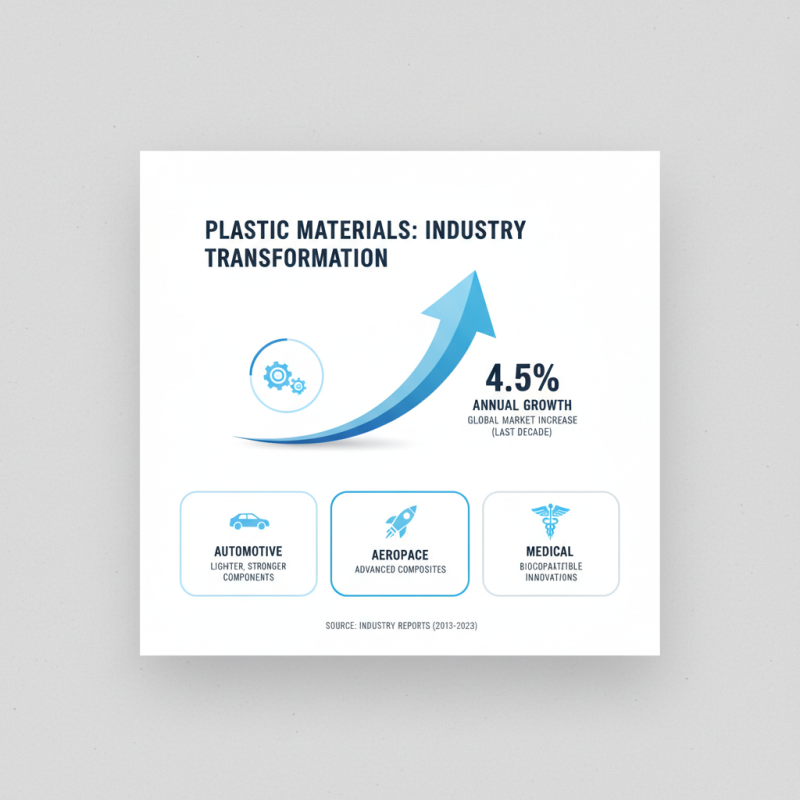

The advancements in plastic materials have significantly transformed industry applications. Over the past decade, the global plastic market has experienced a robust growth rate of around 4.5% per year. This increase reflects the widespread adoption of innovative plastics across various sectors, including automotive, aerospace, and medical industries.

New types of engineered plastics offer enhanced durability and flexibility. For instance, high-performance polymers are now used in components that must withstand extreme temperatures. These materials can reduce weight while maintaining strength, which is crucial for industries looking to improve efficiency. A recent report indicated that using lightweight plastics in automotive design could cut fuel consumption by 10-20%.

Tips: Consider sustainability when selecting materials. Recycled plastics can be a viable option. They often have comparable properties to virgin materials. However, ensure they meet required performance standards.

Despite these advances, challenges remain. Some plastics still lack recyclability, presenting environmental concerns. Also, not all industries adopt new materials quickly. Resistance to change can hinder progress. Keeping abreast of industry standards and customer requirements is vital for ongoing development. Exploring new applications for existing materials could lead to innovative solutions.

Cost-Effectiveness of Plastic Fabrication in Production

Plastic fabrication is a key process for modern industries. It offers an efficient and cost-effective solution for many manufacturing needs. The production methods available today enable companies to create various parts and products quickly, reducing both time and labor costs. In industries like automotive and consumer goods, using plastic can lower expenses significantly.

Making the most of plastic fabrication requires careful planning. Here are some tips:

- Choose the right materials based on strength requirements and cost.

- Assess your designs for manufacturability early in the process. This helps avoid costly revisions later.

- Consider recycling options for waste plastic to reduce environmental impact and costs.

However, it’s important to recognize that not all plastic products are equal. Some designs may look appealing on paper but become expensive to produce. Regularly review production processes to find areas of waste or inefficiency. Streamlining production can enhance cost-effectiveness even more. As industries evolve, the role of thoughtful plastic fabrication will become even more vital.

Sustainability Challenges and Innovations in Plastic Fabrication

Plastic fabrication plays a vital role in modern industries, especially in addressing sustainability challenges. The rise in plastic waste demands innovative approaches. Many industries are now exploring biodegradable and recyclable materials. These materials help reduce the environmental impact significantly.

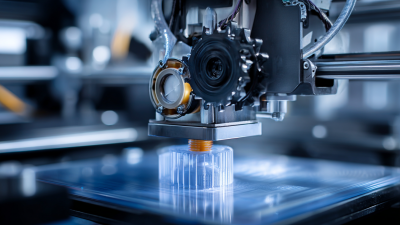

One innovative solution is 3D printing with sustainable plastics. This method minimizes waste compared to traditional fabrication methods. It allows for precise designs and reduces material usage. However, the technology is still evolving. More research is needed to enhance the mechanical properties of these sustainable options.

Tips: Consider using local suppliers for materials. This reduces transportation emissions. Also, explore partnerships with recycling companies. They can help develop closed-loop systems. Innovating in fabrication processes is not just necessary. It encourages businesses to reflect on their practices and find better solutions. Embrace the challenge; improvement starts from within.

Plastic Fabrication in Modern Industries: Key Applications and Sustainability Challenges

Future Trends in Plastic Fabrication for Modern Industries

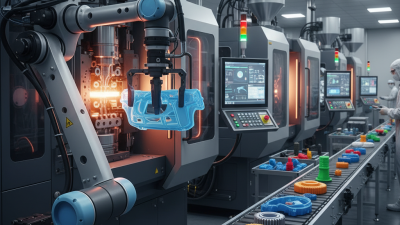

The future of plastic fabrication is poised for transformation. Recent industry reports suggest that the global plastic fabrication market will reach approximately $740 billion by 2027. This growth is driven by advancements in technologies such as 3D printing and injection molding. These innovations not only enhance efficiency but also reduce waste. However, the challenge remains: how to ensure sustainability while meeting increasing demands?

Emerging trends indicate a shift toward bioplastics and recyclable materials. According to a study by the Plastics Industry Association, the use of bioplastics could reduce fossil fuel dependence by 30% by 2030. This is a significant leap, yet many businesses still resist change due to cost concerns. Plastic fabrication must adapt to these market pressures while focusing on eco-friendly practices.

Furthermore, the integration of smart technology into production processes is on the rise. This smart fabrication allows real-time adjustments and quality control. But there are growing concerns about data security and the potential for job displacement. Industries must balance technological advancement with workforce stability. The road ahead is not entirely clear, but the potential for innovation is immense.

Related Posts

-

How to Optimize Plastic Parts Manufacturing for Efficiency and Quality

-

Exploring the Versatility of Cast Acrylic: Creative Applications for Modern Design

-

Top 10 Acrylic Plastic Sheets for Your DIY Projects and Home Improvements

-

How to Get Plexiglass Cut to Size for Your Projects and DIY Ideas

-

Revolutionizing Product Design with Advanced Plastic Prototype Manufacturing Techniques

-

How to Cut and Shape Cast Acrylic Sheets for Your DIY Projects