Posts

How to Optimize Plastic Parts Manufacturing for Efficiency and Quality

Efficient and high-quality plastic parts manufacturing is essential in today's fast-paced industrial landscape. As industries increasingly rely on plastic components for various applications, optimizing the manufacturing process becomes paramount to meet the growing demands for precision and reliability. This introduction explores key strategies and insights that can enhance operational efficiency while maintaining the quality that is critical in sectors such as automotive, consumer goods, and electronics.

The challenges faced in plastic parts manufacturing are multifaceted, ranging from material selection to production techniques. By adopting advanced technologies, streamlining workflows, and implementing best practices in quality control, manufacturers can significantly reduce waste and production time. Emphasizing the synergy between technology and manufacturing processes allows companies to achieve higher standards of excellence while keeping costs in check. This discussion aims to shed light on effective methods that address these challenges, ultimately leading to improved productivity and sustainability in plastic parts manufacturing.

Strategies for Reducing Cycle Times in Plastic Parts Manufacturing

Reducing cycle times in plastic parts manufacturing is critical for improving overall efficiency and ensuring high-quality outputs. According to a report by the Plastics Industry Association, the average injection molding cycle time can significantly impact production costs, with a reduction of even a few seconds leading to substantial savings. Implementing advanced technologies such as robotics and automation can streamline repetitive tasks, thereby minimizing labor time and the chances of human error. Additionally, integrating real-time monitoring systems can help in identifying bottlenecks in the manufacturing process, allowing for quick adjustments and enhancing responsiveness.

Reducing cycle times in plastic parts manufacturing is critical for improving overall efficiency and ensuring high-quality outputs. According to a report by the Plastics Industry Association, the average injection molding cycle time can significantly impact production costs, with a reduction of even a few seconds leading to substantial savings. Implementing advanced technologies such as robotics and automation can streamline repetitive tasks, thereby minimizing labor time and the chances of human error. Additionally, integrating real-time monitoring systems can help in identifying bottlenecks in the manufacturing process, allowing for quick adjustments and enhancing responsiveness.

Moreover, adopting process optimization strategies like mold design enhancements and material selection can also drive efficiency. For instance, utilizing mold flow analysis software can enhance cooling channel design, leading to a more uniform temperature distribution and shorter cooling times. Data from the American Society for Quality indicates that optimizing material properties can yield a 10-15% reduction in cycle times, particularly when using high-performance polymers. Collaborating with material suppliers who can provide insights into the latest developments can further assist in achieving these benefits while maintaining product quality. By focusing on these strategies, manufacturers can effectively reduce cycle times while maintaining their commitment to excellence in plastic parts production.

Incorporating Automation Technologies to Enhance Production Efficiency

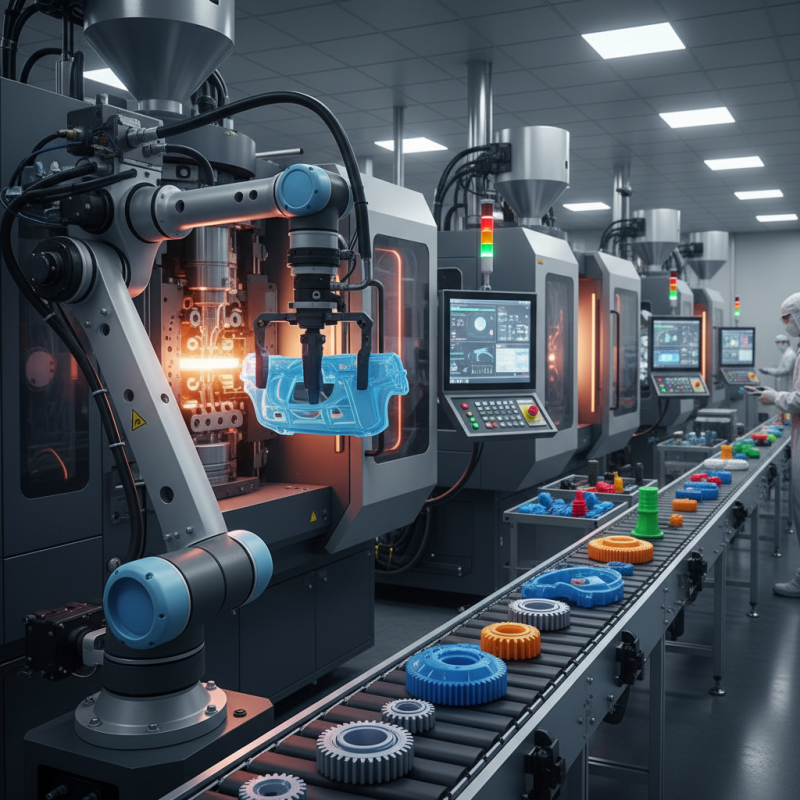

The integration of automation technologies in plastic parts manufacturing is transforming production processes by significantly enhancing efficiency and quality. According to a report by the International Federation of Robotics, the use of industrial robots has increased by approximately 14% annually, indicating a growing trend towards automation in manufacturing sectors. The adoption of these technologies allows for reduced cycle times, minimizing human error, and ensuring consistent product quality. For instance, automated injection molding systems can achieve precision up to 10 microns, enabling manufacturers to produce complex components that meet stringent specifications with ease.

Additionally, automation technologies such as AI-driven predictive maintenance systems are helping manufacturers improve their operational efficiency. A study by McKinsey estimates that predictive maintenance can reduce downtime by up to 50%, resulting in substantial cost savings and increased productivity. By utilizing machine learning algorithms to analyze equipment performance data, manufacturers can anticipate failures and schedule maintenance proactively. This not only extends the lifespan of machinery but also protects against unexpected production halts. As plastic parts manufacturing continues to evolve, embracing these automation technologies is vital for staying competitive in a market that increasingly demands higher quality and faster turnaround times.

How to Optimize Plastic Parts Manufacturing for Efficiency and Quality - Incorporating Automation Technologies to Enhance Production Efficiency

| Parameter | Current Value | Target Value | Improvement Needed (%) |

|---|---|---|---|

| Production Speed (units/hour) | 80 | 120 | 50 |

| Defect Rate (%) | 5 | 2 | 60 |

| Machine Utilization (%) | 65 | 85 | 30 |

| Raw Material Waste (%) | 10 | 4 | 60 |

| Cycle Time (minutes) | 15 | 10 | 33 |

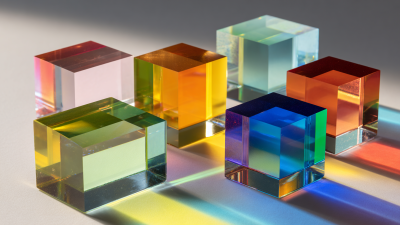

Utilizing Advanced Materials for Improved Durability and Quality

In the quest for enhanced efficiency and quality in plastic parts manufacturing, the selection of advanced materials plays a pivotal role. Utilizing high-performance polymers and composites can significantly improve the durability of plastic components. These materials not only resist wear and tear better than traditional options but also provide greater thermal and chemical stability, crucial for a wide range of applications. By incorporating materials such as reinforced thermoplastics or lightweight composite mixtures, manufacturers can produce parts that endure harsher environments while maintaining structural integrity.

Tips: When considering advanced materials, evaluate the specific requirements of your applications. Conduct thorough material testing to understand how each option performs under varying conditions. Collaboration with material scientists can also help identify innovative solutions that could optimize your production processes.

Furthermore, integrating advanced materials with modern manufacturing techniques, such as additive manufacturing or injection molding with tailored characteristics, leads to more consistent quality in production runs. Enhanced material properties, combined with precision manufacturing methods, ensure that parts are not only produced with high efficiency but also meet the stringent quality standards expected in today’s market.

Tips: Invest in training for your manufacturing team to stay abreast of the latest material advancements and production technologies. Encourage experimentation with different materials to discover unique applications that could offer competitive advantages, ultimately fostering a culture of innovation within your organization.

Implementing Lean Manufacturing Principles in Plastic Part Production

Implementing lean manufacturing principles in plastic part production can significantly enhance both efficiency and quality. Lean manufacturing focuses on minimizing waste while maximizing productivity, making it an ideal approach for the plastic parts industry. By integrating these principles, manufacturers can streamline their operations, reduce lead times, and improve the final product quality.

Tips for optimizing production include regularly assessing and mapping out the workflow. Identify bottlenecks in the production process, such as slow machinery or excessive handling, and address these areas to eliminate delays. Furthermore, adopting just-in-time production techniques can help maintain lean inventory levels and ensure that resources are utilized efficiently.

Another essential tip is to foster a culture of continuous improvement within the workforce. Empowering employees to suggest improvements can lead to innovative solutions that enhance processes and reduce waste. By providing training on lean principles and encouraging cross-functional teams, manufacturers can create an environment where efficiency and quality are everyone's responsibility. This collaborative approach not only motivates employees but also leads to sustainable improvements in plastic parts manufacturing.

Efficiency and Quality in Plastic Parts Manufacturing

Best Practices for Quality Control in Plastic Parts Manufacturing Processes

Quality control is a critical element in the plastic parts manufacturing process, ensuring that products meet both design specifications and customer expectations. One of the best practices for quality control is to implement a robust inspection protocol throughout the manufacturing cycle. This includes performing regular checks at various stages, from raw material selection to final product inspection. By employing techniques such as statistical process control (SPC), manufacturers can monitor variations in production and quickly identify any deviations from expected performance, enabling prompt corrective actions.

Another important practice is to invest in training and development for personnel involved in quality assurance. Educating the workforce on the significance of quality standards and the specific metrics that need to be adhered to ensures a shared understanding of the quality objectives. Regular workshops and training sessions can foster a culture of continuous improvement and attention to detail. Additionally, utilizing automated inspection technologies can enhance the accuracy and efficiency of quality audits, reducing the likelihood of human error while providing reliable data for future adjustments in the manufacturing process.

Related Posts

-

Mastering the Injection Molding Process: Tips for Streamlining Production Efficiency

-

Top 5 Uses of Clear Plastic in Modern Industries: Insights & Trends

-

The Miracle of Cast Acrylic Unveiling Its Versatile Applications in Modern Design

-

Top 10 Tips for Choosing the Best Plastic Board for Your Projects

-

Top 10 Acrylic Plastic Sheets for Your DIY Projects and Home Improvements

-

Why Clear Plastic is the Perfect Choice for Your Packaging Needs