Posts

Why Plastic Prototype Manufacturing is Essential for Successful Product Development

In the fast-paced world of product development, the ability to swiftly iterate on design ideas and validate concepts is paramount. This is where plastic prototype manufacturing plays a crucial role. By offering a tangible representation of a product before it goes into full-scale production, plastic prototypes provide invaluable insights into functionality, aesthetics, and user experience. The process not only helps engineers and designers identify potential issues early but also allows stakeholders to visualize the final product, fostering collaboration and informed decision-making.

As we delve into the "Top 10" reasons why plastic prototype manufacturing is essential for successful product development, we will uncover its multifaceted benefits. From reducing time to market to enabling cost-effective modifications, the advantages of utilizing plastic prototypes are extensive. Each reason highlights how these prototypes serve as a powerful tool in navigating the complexities of product design, ensuring that innovations are not only viable but also meet the needs and expectations of end users. Understanding these benefits is crucial for businesses aiming to streamline their development processes and enhance their competitive edge in the market.

Importance of Rapid Feedback Loops in Prototype Manufacturing

Rapid feedback loops are integral to successful prototype manufacturing, providing the necessary agility to refine products effectively. The essence of these loops lies in the ability to gather insights swiftly during the development process, allowing teams to pivot or iterate based on real-time data. For instance, advancements in generative AI are increasingly being harnessed by agile teams to streamline planning and accelerate feedback mechanisms, thereby enhancing their product development strategies.

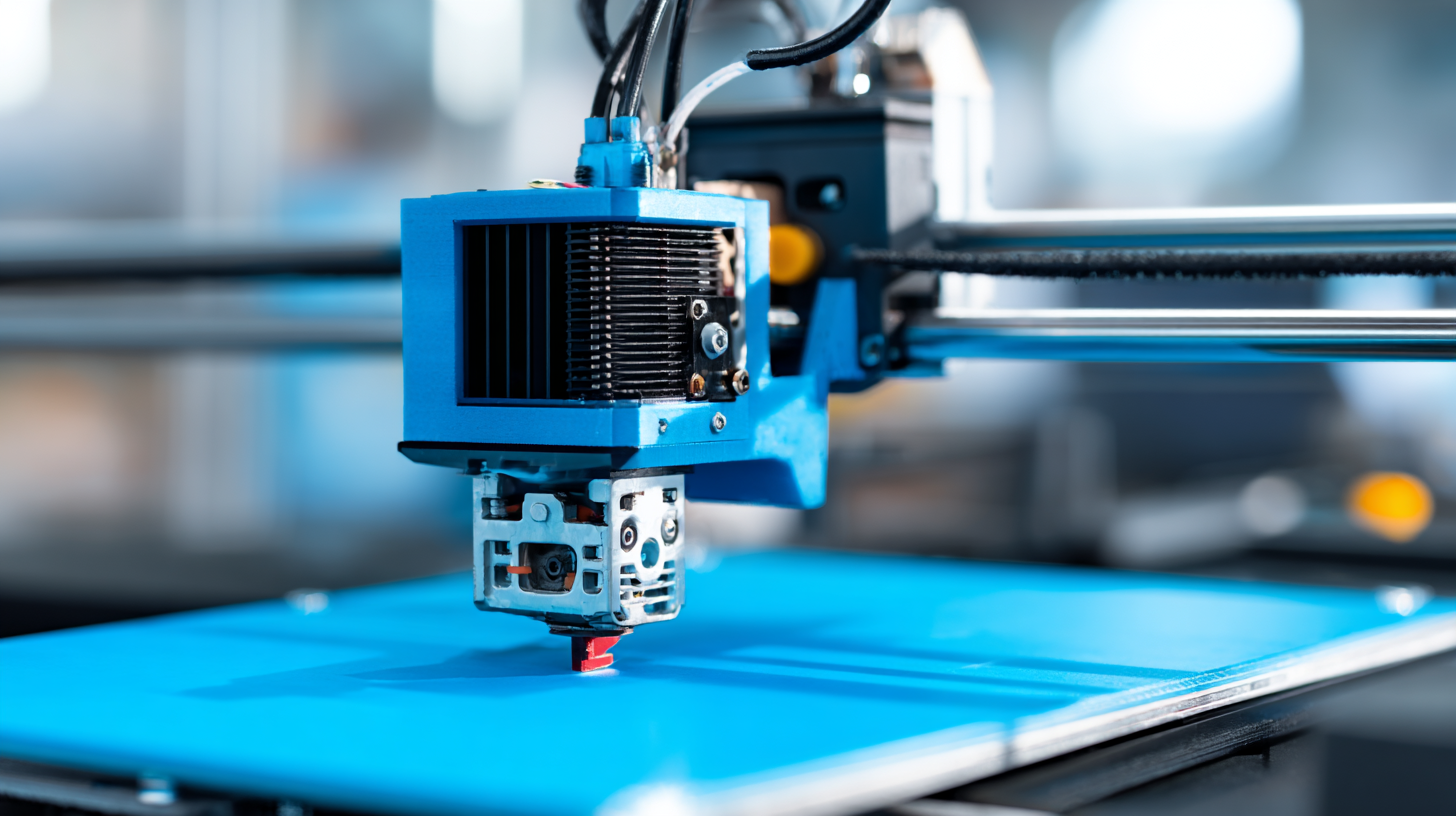

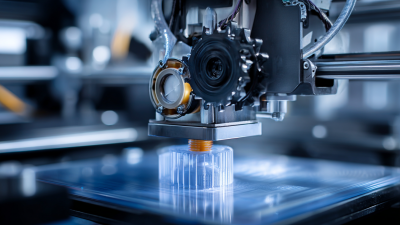

Moreover, the trend towards rapid minimum viable product (MVP) development underscores the importance of these feedback loops. By transforming ideas into market-ready solutions quickly, startups can test their concepts while avoiding drawn-out development cycles. This is vital in today's fast-paced market landscape, where the ability to adapt based on consumer feedback can significantly impact a company's success. As highlighted by the evolution of various prototyping techniques, including sophisticated 3D printing methods, the ability to iterate swiftly can lead to innovative solutions that resonate with end-users.

Key Advantages of Using Plastic Prototypes in Product Testing

In the realm of product development, utilizing plastic prototypes offers significant advantages that can enhance testing and validation processes. According to a report from the Product Development and Management Association (PDMA), companies that engage in prototyping see a 30% reduction in time to market compared to those that skip this critical step. The agility and low cost of plastic prototyping allow teams to iterate on design concepts quickly, enabling designers to gather real user feedback early on.

One of the key benefits of plastic prototypes is their ability to accurately simulate the look and feel of the final product. A 2021 study by the Research and Markets group indicated that over 70% of product developers believe that using accurate prototypes helps to reduce the risk of costly errors later in the production phase. This ensures that design flaws can be identified and addressed before mass production, ultimately leading to higher customer satisfaction and a more successful product launch. In an industry where time is money, the effectiveness of plastic prototypes becomes even more critical in reducing overall project costs and improving product quality.

Why Plastic Prototype Manufacturing is Essential for Successful Product Development - Key Advantages of Using Plastic Prototypes in Product Testing

| Advantage | Description | Impact on Development |

|---|---|---|

| Cost-Effectiveness | Plastic prototypes are cheaper to produce compared to metal or other materials. | Reduces the overall budget and allows for more iterations. |

| Speed of Production | Faster turnaround times due to less complex manufacturing processes. | Accelerates the product development timeline. |

| Design Flexibility | Easier to modify and refine designs based on testing feedback. | Encourages innovation and creativity in product designs. |

| Functional Testing | Allows for realistic testing of functions and ergonomics before mass production. | Identifies potential issues early in the development process. |

| Market Validation | Facilitates gathering consumer feedback through tangible models. | Helps ensure that the final product meets market needs and expectations. |

Cost-Effectiveness of Plastic Prototyping Over Traditional Methods

Plastic prototype manufacturing has emerged as a key player in product development, particularly due to its cost-effectiveness compared to traditional prototyping methods. Traditional techniques often involve extensive material costs and labor-intensive processes, which can significantly inflate project budgets. In contrast, plastic prototyping utilizes materials that are not only less expensive but also faster to produce, enabling designers and engineers to iterate quickly without breaking the bank.

Tips: When considering plastic prototyping, it's essential to select the right type of plastic for your project. Different plastics offer varying levels of flexibility, strength, and durability. Additionally, leveraging 3D printing technology can further reduce costs and lead times, as this method allows for rapid prototyping with minimal waste. By employing these strategies, companies can streamline their product development processes and bring their innovations to market more efficiently.

The financial benefits of plastic prototyping extend beyond just the initial production costs. Rapid prototyping allows businesses to test designs and gather feedback early in the development cycle, minimizing the risk of costly revisions later on. This not only saves money but also ensures that the final product is well-aligned with market needs and consumer expectations.

Enhancing Collaboration Through Iterative Prototype Reviews

Iterative prototype reviews are crucial in the product development process, as they facilitate enhanced collaboration among team members. By creating tangible plastic prototypes, designers and engineers can visualize concepts more clearly, allowing them to engage in constructive discussions. This hands-on approach helps to identify potential flaws early in the development cycle, reducing the risk of costly errors later on. When team members gather to review these prototypes, they can provide immediate feedback, ensuring that everyone is aligned with the project goals and vision.

Furthermore, iterative reviews promote a culture of continuous improvement and innovation. As stakeholders examine each prototype, they can suggest adjustments and enhancements based on their diverse perspectives and expertise. This collaborative atmosphere not only fosters teamwork but also accelerates the decision-making process, as changes can be promptly implemented. Consequently, the iterative nature of prototype reviews leads to more refined products that better meet user needs and preferences, ultimately contributing to a successful product development strategy.

Best Practices for Implementing Plastic Prototyping in Your Workflow

Implementing plastic prototyping in your workflow is crucial for enhancing product development efficiency. According to a report by Product Development and Management Association (PDMA), companies that incorporate prototyping into their development process witness a 50% reduction in time-to-market. This significant reduction is attributed to the early identification of design flaws and the ability to test functionality before committing to production. By utilizing plastic prototyping, teams can iterate on designs rapidly, ensuring that customer feedback is integrated promptly.

Best practices for implementing plastic prototyping involve integrating it early in the design phase. Utilizing advanced technologies such as 3D printing allows for quick iterations and cost-effective material use. The Wohlers Report indicates that the additive manufacturing market is expected to grow to $35.6 billion by 2024, highlighting the increasing reliance on these technologies. Furthermore, collaboration across departments—design, engineering, and marketing—ensures that all perspectives are considered, enhancing product viability. A survey by the Aberdeen Group reveals that organizations with cross-functional teams achieve 20% better project outcomes than those with siloed approaches. By following these best practices, businesses can leverage plastic prototyping to streamline their product development processes effectively.

Related Posts

-

Revolutionizing Product Design with Advanced Plastic Prototype Manufacturing Techniques

-

Mastering the Injection Molding Process: Tips for Streamlining Production Efficiency

-

Discover the Benefits of Custom Cut to Size Plexiglass for Your Home and Business Needs

-

Transform Your Space with Custom Cut to Size Acrylic Sheets for Every Project

-

Exploring the Versatility of Cast Acrylic: Creative Applications for Modern Design

-

Transform Your Space with Clear Acrylic Solutions for Modern Decor