Posts

What is Precision Plastics? A Comprehensive Guide to Applications and Benefits

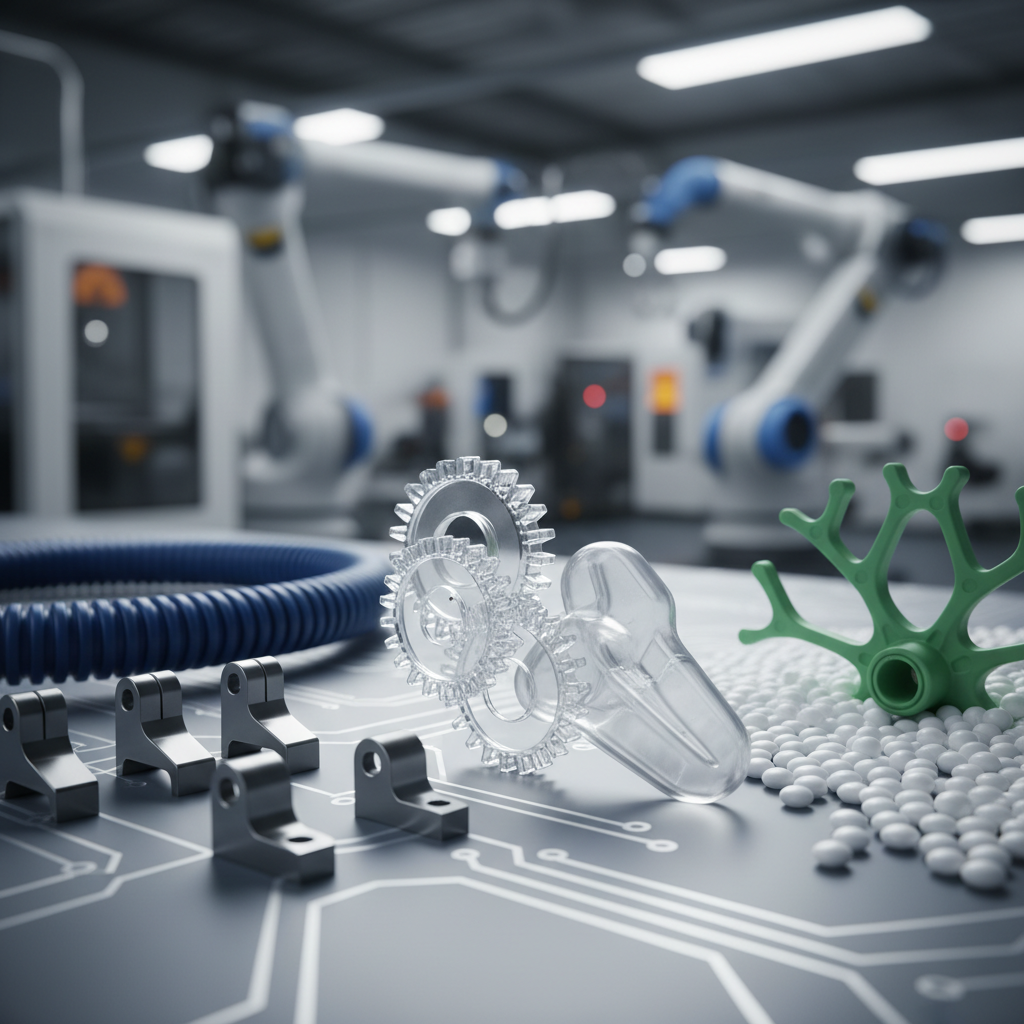

Precision plastics represent a transformative leap in materials technology, delivering unparalleled performance across various industries. As the demand for high-quality, durable, and cost-effective solutions continues to rise, these engineered polymers have carved out a significant niche in sectors ranging from automotive to medical devices. This comprehensive guide explores the applications and benefits of precision plastics, shedding light on why they are increasingly favored for intricate components that require exacting specifications.

In today's fast-paced manufacturing landscape, the ability to produce parts that meet stringent tolerance levels is paramount. Precision plastics offer a unique combination of lightweight properties and remarkable strength, making them ideal for applications where traditional materials may fall short. From their role in enhancing product performance to reducing waste and overall costs, the advantages of precision plastics are manifold. In this guide, we will dive into the top ten applications where precision plastics shine, and discuss how they are shaping the future of design and manufacturing.

Understanding Precision Plastics: Definitions and Key Characteristics

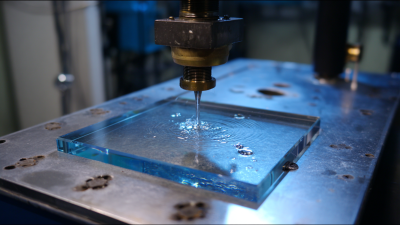

Precision plastics refer to high-performance plastic materials that are engineered to meet stringent specifications in various applications. These materials are characterized by their exceptional dimensional accuracy, consistency, and mechanical properties. The manufacturing processes employed, such as injection molding and CNC machining, allow for the production of complex shapes with tight tolerances, making precision plastics ideal for sectors like aerospace, automotive, and medical devices.

One of the key characteristics of precision plastics is their enhanced durability and resistance to environmental factors such as heat, chemicals, and moisture. This durability not only prolongs the lifespan of components but also ensures reliability in critical applications.

Furthermore, precision plastics can be engineered to exhibit specific traits like low friction, high impact resistance, and lightweight properties, contributing to improved performance and efficiency in their respective fields. Overall, understanding these definitions and key characteristics allows industries to harness the full potential of precision plastics in designing innovative solutions.

Major Applications of Precision Plastics Across Various Industries

Precision plastics play a significant role across various industries, thanks to their unique properties and applications. As the global plastic welding extruder market is projected to reach approximately $986.41 million by 2025 and double to $1.88 billion by 2035, with a compound annual growth rate (CAGR) of 6.7%, it is evident that the demand for precision plastics will continue to rise. The versatility of PVC, one of the most widely used synthetic polymers, further highlights the growing significance of precision plastics. With production capacity reaching 27.26 million tons in China by 2023, PVC's stable growth reflects its essential applications across construction, automotive, and packaging sectors.

In the aerospace industry, the precision plastics market is also expected to expand significantly. Reports indicate that the aerospace plastics market, valued at over $47.6 million in 2019, is anticipated to grow at a CAGR of 8.4% until 2026. This growth is primarily driven by an increase in air passenger traffic and the demand for new aircraft due to emerging travel routes. As industries continue to innovate and expand, the benefits provided by precision plastics—such as enhanced durability, lightweight characteristics, and resistance to environmental factors—will be indispensable across various applications.

Benefits of Using Precision Plastics: Cost, Performance, and Sustainability

Precision plastics have emerged as a vital material choice across various industries due to their remarkable benefits in cost-effectiveness, performance, and sustainability. These engineered materials offer superior accuracy in manufacturing processes, allowing for the production of intricate components that meet stringent specifications. As a result, businesses can reduce waste and enhance productivity, leading to a lower overall cost of production. The longevity and durability of precision plastics also contribute to their cost-effectiveness by minimizing the need for frequent replacements.

In addition to financial advantages, precision plastics are known for their exceptional performance characteristics. They exhibit excellent resistance to chemicals, temperature fluctuations, and wear, making them suitable for demanding applications, including automotive, aerospace, and medical devices. Furthermore, the advancement of eco-friendly manufacturing techniques has positioned precision plastics as a sustainable alternative. By opting for recyclable or biodegradable formulations, industries can significantly reduce their environmental footprint while still benefiting from the high performance required for modern applications. This alignment with sustainability goals not only meets consumer demands but also helps companies comply with regulations and improve their public image.

Market Trends and Innovations in Precision Plastics for 2025

The precision plastics industry is poised for significant growth, fueled by evolving market trends and technological innovations. By 2025, the global engineering plastics market is expected to reach approximately $184.66 billion, reflecting a compound annual growth rate (CAGR) of 5.4% until 2032. This growth is indicative of a broader shift towards higher efficiency and sustainability in manufacturing processes. As industries increasingly seek to reduce their environmental impact, the demand for advanced polymer solutions that offer both precision and eco-friendliness is on the rise.

In specific sectors such as precision agriculture, the market for smart plastics is anticipated to expand dramatically, with projections indicating a increase from $2.78 billion in 2024 to approximately $7.18 billion by 2033. The integration of AI and smart technologies in plastics is set to redefine agricultural practices, enhancing efficiency and productivity through innovative material applications. As companies invest in the development of sophisticated plastic processing machinery, the landscape is shifting towards a future where sustainability and digital intelligence are at the forefront of engineering plastics advancements.

Market Trends in Precision Plastics: 2025 Projections

This bar chart displays the projected growth rates for various industries utilizing precision plastics by the year 2025. As shown, the medical and electronics sectors are anticipated to see the highest growth, highlighting increased demand for precision plastic applications in these areas.

Data-Driven Insights: Growth Projections and Market Dynamics in Precision Plastics Industry

The precision plastics industry is experiencing significant growth, driven by advancements in manufacturing technologies and an increasing demand for high-performance materials across various sectors. With applications ranging from automotive to medical devices, precision plastics offer unparalleled advantages in terms of durability, lightweight structures, and design flexibility. Data-driven insights reveal a robust surge in market dynamics, indicating that the industry is poised to expand at an impressive rate over the coming years.

Market projections suggest that the adoption of precision plastics will continue to rise, fueled by innovations in processing techniques and material science. The shift toward sustainable manufacturing practices is also influencing growth, as companies aim to reduce their environmental footprint while enhancing product performance. As industries increasingly prioritize customization and precision, the demand for specialized plastic solutions will become ever more critical, marking a transformative era in the precision plastics market.

Related Posts

-

Top 5 Benefits of Using Plexiglass Sheets Cut to Size for Your Projects

-

Exploring the Versatility of Clear Plastic Sheets: 10 Innovative Applications Backed by Industry Insights

-

2025 Top 5 Colored Acrylic Sheets for Creative Projects and Designs

-

Mastering the Injection Molding Process: Tips for Streamlining Production Efficiency

-

The Art and Science of Acrylic Fabrication Techniques for Creative Projects

-

Discover the Benefits of Custom Cut to Size Plexiglass for Your Home and Business Needs