Posts

Revolutionizing Product Design with Advanced Plastic Prototype Manufacturing Techniques

In recent years, the landscape of product design has undergone a significant transformation, largely driven by advancements in plastic prototype manufacturing. According to a report by Smithers Pira, the global market for 3D printing and prototyping is projected to reach $30.5 billion by 2025, reflecting a growing demand for efficient and cost-effective manufacturing solutions. These advanced plastic prototype manufacturing techniques not only facilitate rapid prototyping but also enhance the precision and durability of prototypes, allowing designers to iterate quickly and bring innovative products to market faster. As industries increasingly emphasize sustainability, manufacturers are exploring eco-friendly materials, thereby aligning with global goals for reduced environmental impact. This revolution in product design underscores the critical role of sophisticated prototyping technologies in achieving competitive advantages and meeting consumer demands in an ever-evolving marketplace.

Innovative Plastic Prototype Manufacturing Techniques Enhancing Product Development Efficiency

In the fast-paced world of product development, innovative plastic prototype manufacturing techniques are crucial for enhancing efficiency and streamlining the design process. Advanced methodologies, such as additive manufacturing and rapid prototyping, allow designers to create highly detailed prototypes at an unprecedented pace. These techniques enable constant iteration, allowing teams to test and refine their concepts quickly, thereby reducing the time from ideation to final product.

Moreover, the integration of digital tools and computer-aided design (CAD) software has further transformed the prototype manufacturing landscape. These technologies facilitate precise modeling, enabling manufacturers to visualize and modify designs before physical production begins. This not only minimizes material waste but also significantly cuts down production costs. By leveraging these innovative techniques, companies can respond to market demands more agilely, ensuring their products are not only functional but also aligned with consumer expectations.

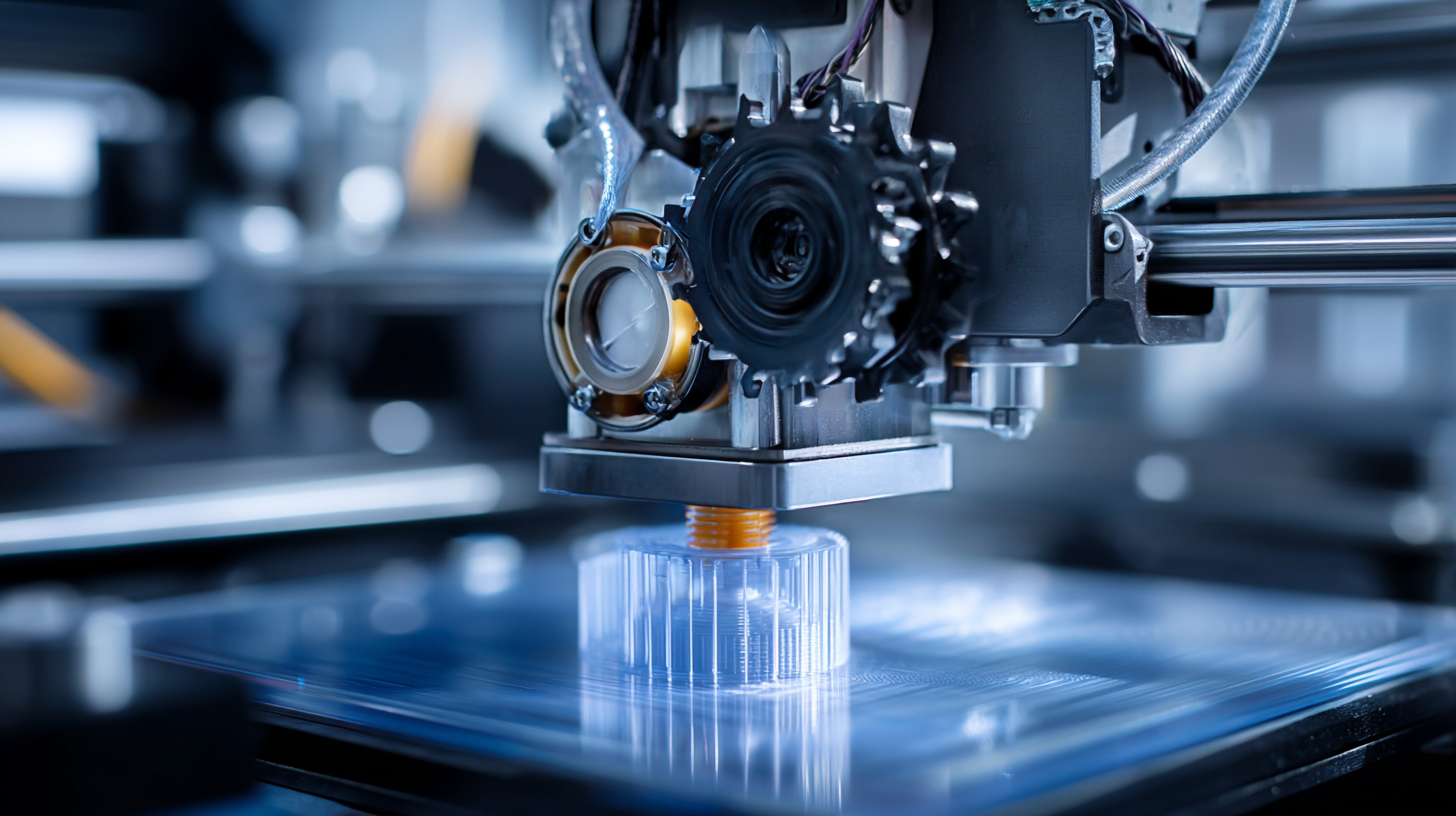

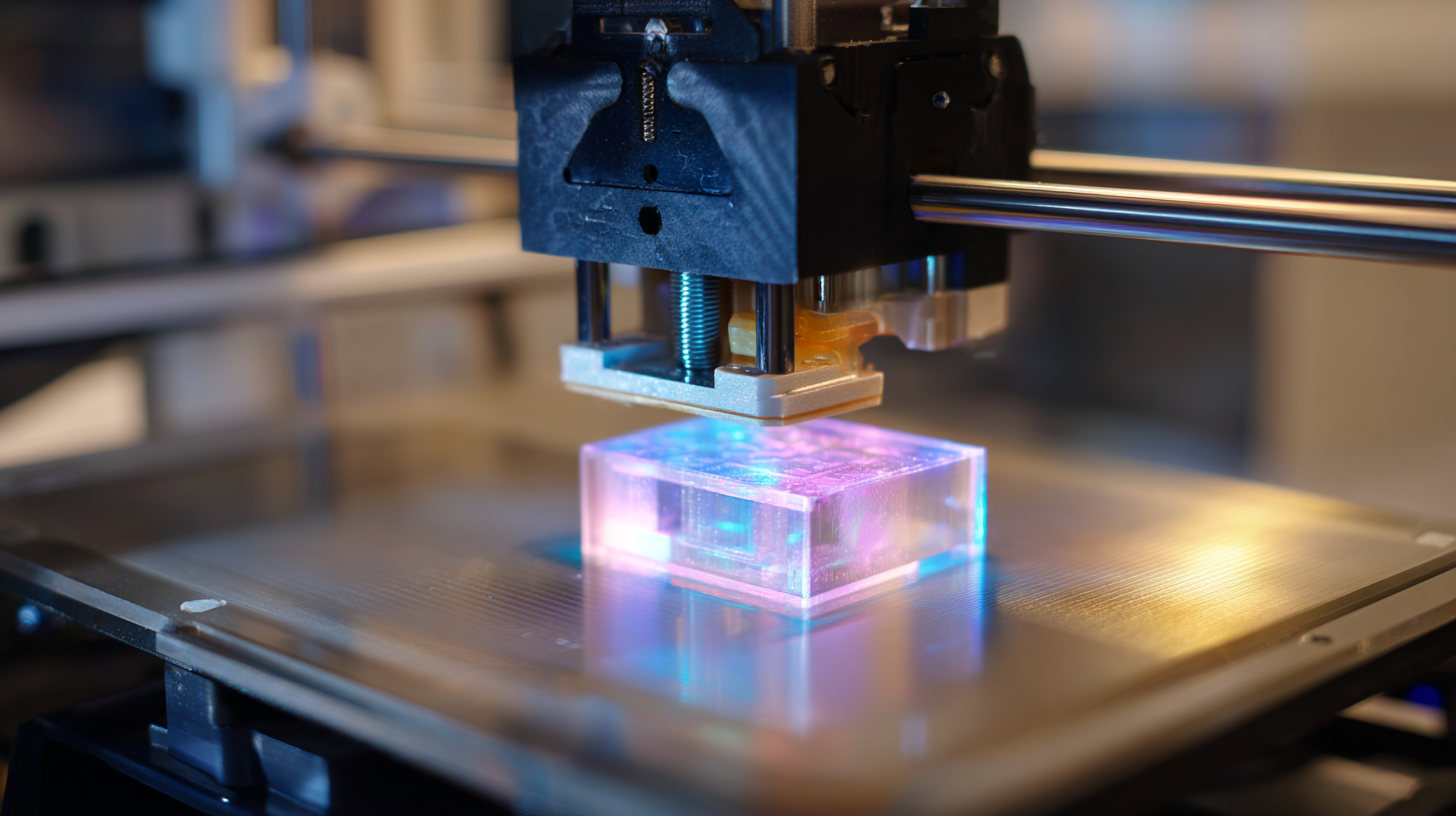

Impact of Advanced 3D Printing Technologies on Plastic Prototype Creation

Advancements in 3D printing technologies are transforming the landscape of plastic prototype creation, leading to unprecedented efficiency and creativity in product design. Traditional manufacturing methods often require extensive lead times and significant costs, particularly when it comes to creating custom prototypes. However, with the latest 3D printing advancements, designers can swiftly iterate their concepts, producing high-quality prototypes in a fraction of the time. This acceleration in the design process allows for enhanced collaboration and faster feedback loops, ultimately resulting in more innovative products that align closely with market demands.

Furthermore, the versatility of advanced 3D printing techniques enables the use of a wider array of plastic materials, each offering unique properties tailored to specific applications. From flexible filaments for ergonomic designs to durable composites for robust end-use products, designers can explore new frontiers in functionality and aesthetics. By leveraging these capabilities, companies can experiment with complex geometries and intricate details that were previously unattainable with conventional manufacturing methods. As a result, the impact of these technologies extends beyond mere speed, fostering a new wave of creativity in product design that is shaping the future of various industries.

Cost-Effectiveness of Using Advanced Plastic Materials in Prototype Manufacturing

The use of advanced plastic materials in prototype manufacturing is transforming the landscape of product design. By leveraging these innovative materials, manufacturers can significantly reduce production costs while enhancing the quality and functionality of their prototypes. Advanced plastics offer durability, versatility, and ease of fabrication, making them an ideal choice for various applications in industries ranging from automotive to consumer electronics.

**Tips:** When selecting advanced plastic materials for prototyping, consider factors such as tensile strength, temperature resistance, and ease of machining. Conducting a cost-benefit analysis can also help you determine which material aligns best with your project goals without sacrificing quality.

Furthermore, the ability to rapidly iterate designs using advanced plastics allows for more efficient testing and feedback cycles. This not only speeds up the development process but also minimizes waste, ultimately leading to a more cost-effective production environment. Integrating these materials into your workflow can pave the way for innovative products while keeping budget constraints in check.

**Tips:** Collaborate with material suppliers and manufacturers to explore the full spectrum of advanced plastic options available. This partnership can lead to discovering unique materials that may offer further cost and performance advantages.

Revolutionizing Product Design with Advanced Plastic Prototype Manufacturing Techniques - Cost-Effectiveness of Using Advanced Plastic Materials in Prototype Manufacturing

| Prototype Type | Material Used | Cost per Unit ($) | Production Time (Days) | Durability Rating (1-10) | Applications |

|---|---|---|---|---|---|

| Consumer Electronics | ABS Plastic | 30 | 10 | 8 | Smartphones, Laptops |

| Automotive Parts | Nylon | 45 | 15 | 9 | Bumpers, Interior Components |

| Medical Devices | Polycarbonate | 60 | 12 | 10 | Surgical Tools, Prosthetics |

| Consumer Goods | Polypropylene | 25 | 8 | 7 | Containers, Household Items |

| Aerospace Components | PEEK (Polyether Ether Ketone) | 120 | 20 | 10 | Structural Components |

Time-to-Market Reduction Through Rapid Prototyping Strategies in the Plastics Industry

In today's fast-paced market, the ability to quickly bring a product from concept to reality is crucial. Rapid prototyping strategies in the plastics industry are revolutionizing product design by significantly reducing time-to-market. Advanced manufacturing techniques allow designers to create and test prototypes swiftly, enabling them to make informed decisions and iterate designs with speed and efficiency. This not only shortens development cycles but also helps companies respond to consumer feedback and market demands much faster.

**Tips for Rapid Prototyping Success:**

1. Utilize 3D printing technology to create functional prototypes quickly. This reduces material waste and allows for easy modification during the design process.

2. Engage cross-functional teams early in the prototyping phase. Incorporating insights from marketing, engineering, and manufacturing departments can lead to more robust designs that meet market expectations.

3. Leverage simulation software to test prototypes virtually before physical manufacturing begins. This can save time and resources while allowing for optimization of designs.

By adopting these rapid prototyping strategies, companies in the plastics industry can not only enhance their innovation capabilities but also stay ahead of the competition in a rapidly evolving marketplace.

Impact of Rapid Prototyping on Time-to-Market in the Plastics Industry

Sustainability in Plastic Prototype Manufacturing: The Shift Towards Eco-Friendly Materials

In recent years, the demand for sustainability in product design has prompted a significant shift towards eco-friendly materials in plastic prototype manufacturing. Traditional plastics have long been criticized for their environmental impact, leading many companies to explore biodegradable alternatives and recycled materials. By embracing innovative materials such as bioplastics or reclaimed plastics, manufacturers not only reduce their ecological footprint but also cater to increasingly eco-conscious consumers.

Tip: When selecting materials for plastic prototyping, prioritize those with certifications indicating their eco-friendly properties. Look for options like PLA or PHA that offer biodegradability and are sourced from renewable resources.

Moreover, advancements in technology have improved the efficiency of these alternative materials. Additive manufacturing processes, such as 3D printing, can minimize waste and allow for more intricate designs, making sustainable prototyping viable without compromising quality or performance. This technological evolution supports brands in creating not only innovative products but also a positive environmental impact.

Tip: Always conduct a lifecycle assessment of your chosen materials to understand their long-term environmental implications. This will help in making informed decisions that align with your sustainability goals.

Related Posts

-

Mastering the Injection Molding Process: Tips for Streamlining Production Efficiency

-

The Ultimate Guide to Choosing the Right Clear Plastic for Your Projects

-

Discover the Benefits of Custom Cut to Size Plexiglass for Your Home and Business Needs

-

The Miracle of Cast Acrylic Unveiling Its Versatile Applications in Modern Design

-

Exploring the Versatility of Cast Acrylic: Creative Applications for Modern Design