Posts

Top 10 Tips for Choosing the Best Plastic Board for Your Projects

When embarking on a project that requires the right materials, choosing the best plastic board can significantly influence the outcome. As industry expert Dr. Emily Thompson, a renowned materials scientist, once stated, “The quality of your plastic board can make or break the integrity of your work.” With a myriad of options available, each varying in durability, flexibility, and suitability for specific applications, the selection process can be daunting.

Understanding the characteristics that define a quality plastic board is essential for achieving optimal results in your projects. Factors such as thickness, color, and UV resistance all play a significant role in the functionality and longevity of the material. By considering these aspects, along with insights from experts like Dr. Thompson, you can ensure a wise investment that aligns with your project goals. In this guide, we will explore the top 10 tips for choosing the best plastic board, equipping you with the knowledge required to make informed decisions and elevate your project to new heights.

Understanding Different Types of Plastic Boards for Projects

When selecting the right plastic board for your project, it's essential to understand the various types available, as each type has distinct characteristics suited for different applications. Common types include PVC, acrylic, and polycarbonate boards. PVC boards are widely used for their durability and resistance to moisture, making them ideal for outdoor applications and signage. They can be easily cut and shaped, which is appealing for DIY projects.

Acrylic boards, on the other hand, offer a high level of clarity and gloss, resembling glass but being significantly more lightweight and shatter-resistant. This makes them perfect for display cases or decorative elements. Polycarbonate boards are known for their exceptional strength and impact resistance, making them suitable for more demanding environments, such as safety shields or protective barriers. When choosing a plastic board, consider factors like UV resistance, temperature tolerance, and ease of fabrication, as these will influence the longevity and functionality of your project.

Top 10 Tips for Choosing the Best Plastic Board for Your Projects - Understanding Different Types of Plastic Boards for Projects

| Tip | Type of Plastic Board | Best Use Cases | Advantages | Disadvantages |

|---|---|---|---|---|

| 1. Consider Your Project Requirements | PVC Board | Signage, Display Boards | Durable, Weather-Resistant | Can warp in extreme temperatures |

| 2. Evaluate Weight and Thickness | Polycarbonate Board | Windows, Roofs | High impact resistance, Lightweight | Can scratch easily |

| 3. Assess Cost vs Budget | Acrylic Board | Aquariums, Displays | Crystal clear, Lightweight | More expensive than PVC |

| 4. Check for Compatibility with Adhesives | HDPE Board | Cutting boards, Playground equipment | High chemical resistance, Durable | Difficult to bond with adhesives |

| 5. Understand the Environmental Factors | Polypropylene Board | Packaging, Automotive parts | Lightweight, Recyclable | Lower impact resistance |

| 6. Look for UV Resistance | ABS Board | 3D printing, Consumer products | Good strength-to-weight ratio | Can be brittle |

| 7. Research Surface Finishes | Foam PVC Board | Interior signage, Exhibitions | Lightweight, Smooth surface | Less rigid compared to solid PVC |

| 8. Consider Ease of Fabrication | Expanded PVC Board | Sign making, Molding | Easy to cut, Lightweight | Not as durable as solid boards |

| 9. Check Fire Rating | Flame Retardant Board | Construction, Safety signage | Increased safety in fire-prone areas | Can be more expensive |

| 10. Consult with Experts | Custom Plastic Board Solutions | Specialty applications, Prototypes | Tailored to specific needs | Potentially longer lead times |

Key Factors to Consider When Selecting Plastic Boards

When selecting the best plastic board for your projects, it’s essential to consider key factors that can significantly influence your project's success. One primary aspect is the application of the plastic board. For instance, if you’re working on outdoor projects, you need to ensure that the material is UV resistant and suitable for various weather conditions. Reports indicate that the global market for corrugated plastic boards is projected to grow from $3.26 billion in 2024 to $3.74 billion by 2033, highlighting the increasing demand for durable and versatile plastic materials in various applications.

Another important factor is the thickness and weight of the board. Thicker boards may offer enhanced durability and better insulation properties, while lighter ones can be more manageable for DIY projects or temporary setups. Furthermore, the type of plastic, whether polypropylene, polyethylene, or PVC, will also affect the board's flexibility and sturdiness. As the market evolves, being informed about the latest materials and trends will help you make a more strategic choice for your specific needs.

**Tip**: Always check if the plastic board is recyclable, as sustainability is becoming a critical consideration in project planning. Additionally, consider the board's edge finish; a smooth edge can enhance safety in projects that require frequent handling or exposure to the public.

Top 10 Tips for Choosing the Best Plastic Board for Your Projects

Evaluating Thickness and Durability of Plastic Boards

When selecting a plastic board for your projects, evaluating thickness and durability is crucial. The thickness of the board directly impacts its strength and performance. For example, thicker boards tend to bear more weight and resist bending or warping, making them ideal for structural applications. Conversely, thinner boards are often more lightweight and flexible, suitable for projects that require easy manipulation or temporary solutions. It's essential to match the thickness of the board with the demands of your specific project to ensure optimal results.

Durability is another key factor in choosing the right plastic board. Look for materials that are resistant to environmental factors such as UV exposure, water, and chemicals. High-quality plastic boards, like polycarbonate or PVC, typically offer enhanced durability and longevity compared to their lower-quality counterparts. Additionally, consider the board's surface finish; a smooth finish may be beneficial for aesthetic projects, while a textured surface could provide better grip and scratch resistance.

When evaluating options, here are a few tips: always check the manufacturer’s specifications for both thickness and durability ratings, and don’t hesitate to ask for samples. This can help you gauge how well the board will perform in your unique context. Also, researching user reviews can provide valuable insights into the real-world performance of different plastic boards.

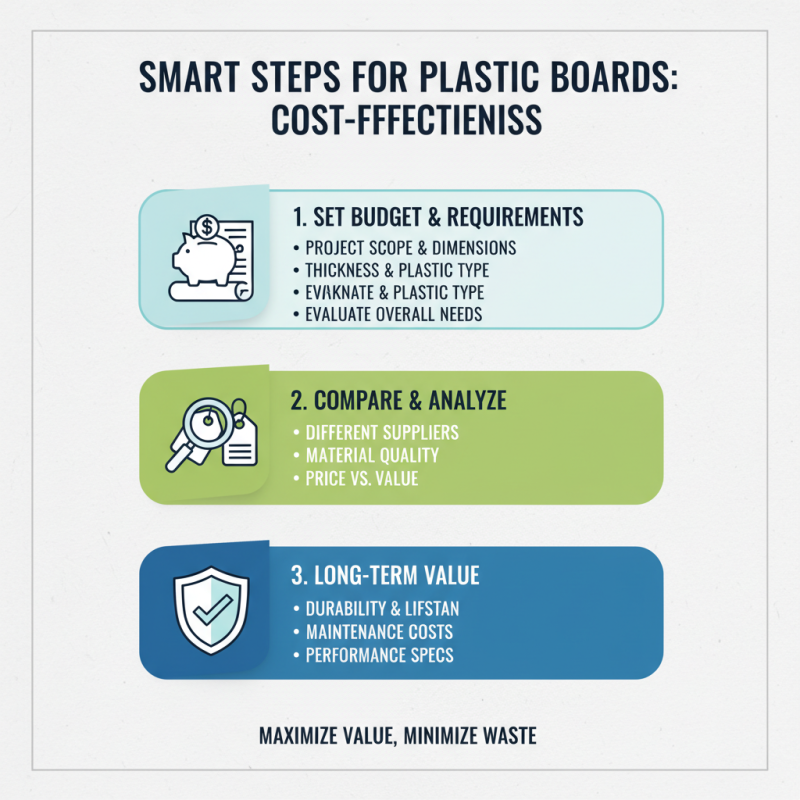

Assessing Cost-Effectiveness and Budget for Your Project

When embarking on a project that requires the use of plastic boards, assessing cost-effectiveness is crucial. The first step is to establish a clear budget, which involves evaluating the overall project requirements. Consider the dimensions, thickness, and type of plastic board needed, as these factors will directly influence price. It’s advisable to compare prices from different suppliers while also considering the quality of materials; a lower price may not always correlate with good value if the boards do not meet your project’s specifications.

Additionally, understanding the long-term benefits of investing in higher-quality boards can enhance cost-effectiveness. While the initial outlay might be higher, durable plastic boards can save money in the long run through reduced replacement and maintenance costs. Look for options that offer warranties and positive customer reviews, as these indicators can guide you towards making a prudent financial choice for your project. Balancing short-term costs with long-term value will ensure that your investment in plastic boards is sound and meets the demands of your project effectively.

Exploring the Environmental Impact of Plastic Board Choices

When selecting a plastic board for your projects, understanding the environmental impact of your choices is crucial. Many plastic boards are manufactured from materials that are not biodegradable and can contribute to the growing problem of landfills. Opting for boards made from recycled plastics can significantly reduce this impact, helping to conserve natural resources and minimize waste. It's essential to look for manufacturers who prioritize sustainability and offer products that are certified as eco-friendly.

Moreover, the production processes used for plastic boards can vary widely in their environmental footprints. Some methods are more energy-intensive than others, releasing higher levels of greenhouse gases into the atmosphere. Choosing boards that are produced with less impactful methods, or those made from renewable resources, can help reduce your project's overall carbon footprint. By considering these factors and making informed choices, you can create projects that not only meet your needs but also align with sustainable practices and contribute positively to the environment.

Related Posts

-

2025 Top 5 Colored Acrylic Sheets for Creative Projects and Designs

-

What is Precision Plastics? A Comprehensive Guide to Applications and Benefits

-

Transform Your Space with Clear Acrylic Solutions for Modern Decor

-

2025 Top 5 Colored Acrylic Sheets for Stunning Home Decor and DIY Projects

-

Exploring the Versatility of Cast Acrylic: Creative Applications for Modern Design

-

Revolutionizing Product Design with Advanced Plastic Prototype Manufacturing Techniques