Posts

2026 Top Trends in Plastic Fabrication Innovations and Applications?

The landscape of plastic fabrication is evolving rapidly. By 2026, innovations in this field are set to redefine industries. According to a recent market report, the global market for plastic fabrication is projected to reach $600 billion by 2026. This surge highlights the crucial role plastic fabrication plays in manufacturing and design.

Expert Dr. Emily Johnson, a leader in polymer engineering, emphasizes, “Investing in newer technologies will propel the plastic fabrication industry forward.” Innovations such as 3D printing and smart materials are gaining traction. Companies are exploring sustainable practices in their production processes. However, challenges remain. While advancements are promising, they also raise questions about waste management and material recyclability.

The industry must navigate these complexities to ensure responsible growth. Striking a balance between innovation and sustainability is essential. Plastic fabrication has incredible potential, but it also requires reflection on its environmental impact. As we look forward, the trends in this sector will shape our understanding of materials and their applications.

Emerging Technologies in Plastic Fabrication for 2026

As we head toward 2026, plastic fabrication is evolving rapidly. New technologies are redefining how we shape and use plastics. Additive manufacturing is at the forefront of this transformation. It allows for intricate designs that traditional methods cannot achieve. Imagine a world where 3D printing creates complex components faster and with less waste.

Moreover, bioplastics are gaining traction. These materials promise to reduce environmental impact. They are derived from renewable resources, making them a sustainable option. However, challenges remain in scaling production and maintaining quality. Innovations must also focus on balancing cost-effectiveness with performance.

Another key trend is smart materials. These plastics can respond to environmental stimuli, such as light or temperature. It's fascinating yet complicated. Integrating sensors could enhance functionality, but it raises questions about durability and safety. The journey ahead is filled with potential and obstacles. Each advancement invites us to reflect on sustainability and efficiency.

Sustainable Materials and Their Impact on Plastic Manufacturing

Sustainable materials are changing plastic manufacturing. The focus on eco-friendly options is growing. Bioplastics are becoming more common in various industries. They are made from renewable resources, like corn and sugarcane. This shift helps reduce dependence on fossil fuels.

Recycling is another key aspect. Many companies are exploring ways to enhance recycled plastic's quality. The challenge lies in overcoming the stigma around recycled materials. Often, they are seen as inferior. However, innovative processes are improving their properties, making them more viable.

Sustainability requires ongoing commitment. There are still concerns about the full lifecycle of these materials. For example, not all bioplastics are biodegradable. Some can still create long-term waste. Manufacturers must carefully consider these factors. Balancing innovation with environmental responsibility is crucial for the future of plastic fabrication.

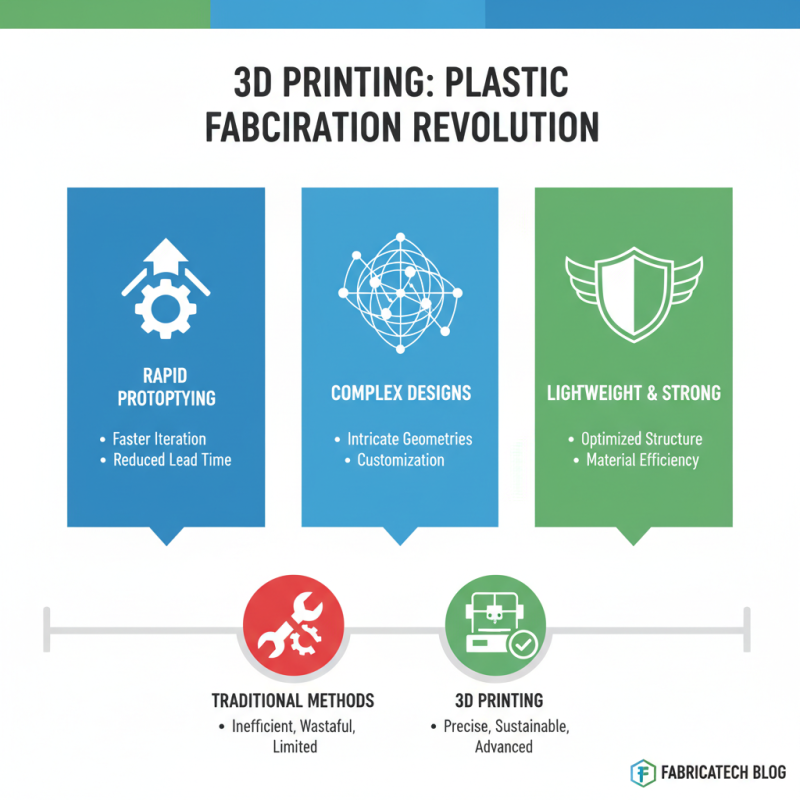

Innovative Applications of 3D Printing in Plastic Fabrication

Innovative applications of 3D printing are transforming plastic fabrication. This technology allows for rapid prototyping and complex designs that were once difficult to produce. Imagine creating intricate geometries that are lightweight yet strong. Traditional methods often struggle to achieve these results, leading to waste and inefficiency.

In sectors like healthcare, 3D printing is paving new paths. Customized implants and prosthetics are now more accessible. However, the materials used must be carefully selected to ensure safety and biocompatibility. Not every plastic is suitable, and this is a point worth reflecting on. It's crucial to continue research and development in this area.

The automotive industry is also leveraging 3D printing for efficient part production. Cars can be made lighter and more fuel-efficient. But challenges remain in terms of material durability and cost. Success requires ongoing collaboration between engineers and designers. Innovation is exciting, but it also raises questions. How can we ensure sustainable practices while advancing technology?

Artificial Intelligence in Optimizing Plastic Production Processes

Artificial Intelligence (AI) is changing the landscape of plastic fabrication. It enhances efficiency and reduces waste in production processes. Manufacturers are now using AI to monitor machine performance in real-time. This helps in predicting failures and minimizing downtime. However, reliance on AI also brings challenges. Workers may feel displaced or unsure about their roles. It is essential to strike a balance between technology and human input.

The use of AI algorithms allows for the optimization of material usage. Sophisticated software can analyze different formulations to find the most cost-effective options. This results in less scrap and lower overall costs. Yet, as companies adopt these technologies, they must consider data privacy and security. Not all firms are prepared to handle sensitive information properly. There’s a risk that over-automation could create vulnerabilities in production.

Moreover, AI can improve design processes by simulating various scenarios. This functionality enables designers to explore innovative ideas quickly. But there is a danger in over-relying on simulations. Real-world conditions may differ significantly from modeled scenarios. Experimentation remains crucial, despite the allure of AI-driven efficiencies. Balancing innovation with traditional methods could yield the best results.

2026 Trends in Plastic Fabrication Innovations

Future Trends in Recycling and Circular Economy for Plastic Products

The future of recycling and the circular economy is crucial for plastic products. As we look toward 2026, innovative approaches are emerging. One major trend is the increased use of biodegradable materials. These materials break down more easily, reducing waste in landfills. Yet, challenges remain. Many consumers still lack awareness about proper disposal.

Another important aspect is advanced sorting technologies. Automated systems can identify and separate plastic types more efficiently. This boosts recycling rates and supports a circular economy. However, technology alone isn’t enough. Community engagement and education are essential. People must understand the significance of recycling.

Moreover, the concept of upcycling is gaining traction. Creative uses for discarded plastics can transform waste into art or functional items. This approach encourages sustainability but also raises questions. How can we ensure quality and durability? These reflections will guide the path forward, as we strive for deeper integration of recycling efforts in our daily lives.

2026 Top Trends in Plastic Fabrication Innovations and Applications

| Trend | Description | Impact Area | Estimated Adoption Year |

|---|---|---|---|

| Biodegradable Plastics | Innovations in materials that break down naturally. | Environment & Waste Management | 2026 |

| 3D Printing of Plastics | Advanced methods for custom plastic manufacturing. | Manufacturing | 2025 |

| Recycled Content in Packaging | Incorporating recycled materials into packaging solutions. | Packaging Industry | 2026 |

| Smart Plastics | Integration of sensors for tracking and monitoring. | Technology & Electronics | 2027 |

| Circular Economy Practices | Focus on reducing, reusing, and recycling plastics. | Economics & Environment | 2026 |

Related Posts

-

Why is Plastic Fabrication Important for Modern Industries?

-

Exploring the Versatility of Clear Plastic Sheets: 10 Innovative Applications Backed by Industry Insights

-

Top 10 Best Plastic Panels for Your Home and Garden?

-

The Ultimate Guide to Choosing the Right Clear Plastic for Your Projects

-

10 Best Plastic Injection Techniques for Optimal Manufacturing Efficiency

-

10 Essential Tips for Acrylic Fabrication Success in 2023 Based on Industry Data