Posts

The Ultimate Guide to Acrylic Plastic Top Types for 2025

In the rapidly evolving world of materials, acrylic plastic continues to stand out as a versatile and innovative option for various applications. As we approach 2025, understanding the different types of acrylic plastic tops and their specific use cases becomes increasingly essential for architects, designers, and manufacturers. According to Jonathan Turner, a leading expert in the acrylic plastic industry, “The future of acrylic plastic is not just in its clarity and aesthetics; it's in its adaptability to meet the demands of modern design.” This insight emphasizes the pivotal role acrylic plastic plays in shaping contemporary environments.

With an array of options available, selecting the right acrylic plastic top can enhance both functionality and visual appeal. From maintaining the brilliance of light transmission to ensuring durability against environmental factors, the choices in 2025 will likely reflect both technological advancements and sustainability considerations. As we delve deeper into this guide, we will explore various types of acrylic plastic tops, their unique features, and how they can be effectively utilized in today's design and manufacturing landscapes. This comprehensive overview aims to equip you with the knowledge necessary to make informed decisions in your next project.

Overview of Acrylic Plastics and Their Applications

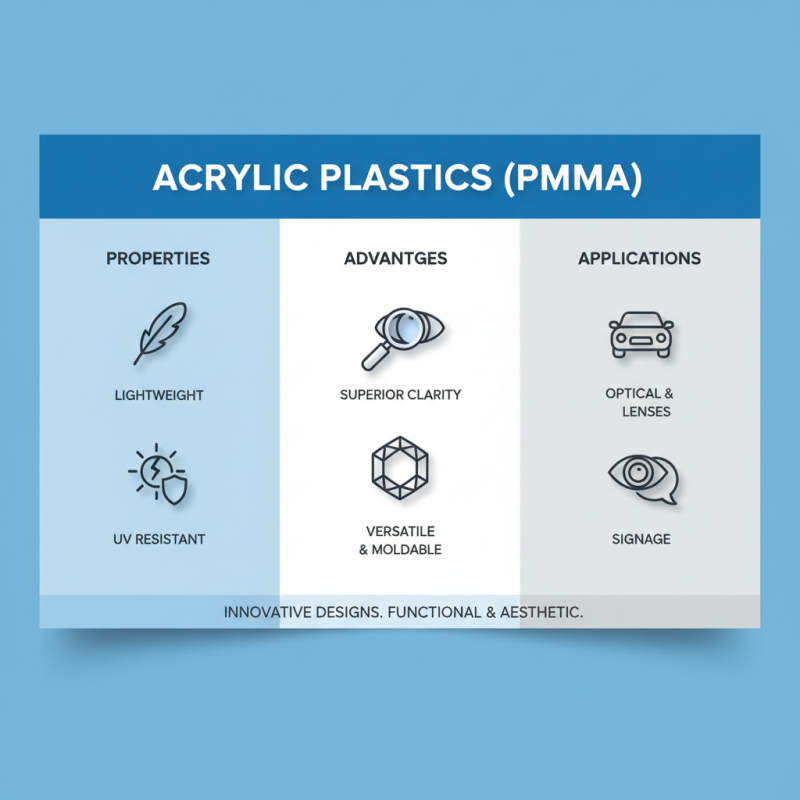

Acrylic plastics, also known as polymethyl methacrylate (PMMA), have gained popularity due to their versatility and extensive range of applications. This lightweight and impact-resistant material offers superior clarity and UV resistance, making it an ideal choice for various industries. From automotive components to optical lenses, and even signage, acrylic plastics combine functionality with aesthetic appeal. Their ability to be molded into complex shapes and sizes further expands their utility, allowing for innovative designs and solutions in both commercial and residential settings.

In addition to their robust physical properties, acrylic plastics are also favored for their ease of fabrication. They can be easily cut, drilled, and polished, making them an accessible choice for DIY projects and professional manufacturing alike. Their inherent flexibility allows for customization, catering to specific needs across multiple sectors, including healthcare, construction, and advertising. As industries increasingly adopt sustainable practices, the recyclability of acrylic plastics adds to their appeal, positioning them as a practical option for environmentally-conscious designs. As we approach 2025, the advancements in acrylic plastic technology will likely open new avenues in applications and enhance their role in our everyday lives.

Key Features of Different Acrylic Plastic Types

When it comes to selecting acrylic plastic, understanding the different types available can significantly impact your project’s outcome in 2025. Among the most prominent types are cast acrylic, extruded acrylic, and cell-cast acrylic.

Cast acrylic tends to offer superior clarity and rigidity, making it ideal for applications that require sharp optics and aesthetics, such as signage and displays. According to industry reports, cast acrylic sheets display a light transmittance rate of over 92%, ensuring brilliant color fidelity and visual appeal.

Extruded acrylic, on the other hand, is known for its ease of fabrication and is commonly used for applications requiring machined edges and thin sheets. It is often less expensive than its cast counterpart; however, it may not achieve the same optical clarity. Current market research indicates that extruded acrylic’s flexibility allows for various applications, particularly in furniture and lighting designs where complex shapes are necessary.

The demand for extruded types has surged, with projections suggesting that it will account for over 40% of the acrylic market share by 2025.

Lastly, cell-cast acrylic, while similar to cast acrylic, has unique properties suitable for specialized uses. It is often employed in high-stress environments due to its resistance to impact and temperature variations. Its market presence is expected to grow, driven by industries such as automotive and aerospace, which require materials that can withstand demanding conditions.

Overall, by understanding these key features and variations in acrylic types, stakeholders can better tailor their selections to meet specific project needs and specifications.

Comparison of Top Acrylic Plastic Types for 2025

When considering acrylic plastics for various applications in 2025, several key types stand out due to their unique properties and advantages. The most common types include cast acrylic, extruded acrylic, and impact-modified acrylic. Cast acrylic, renowned for its clarity and optical quality, is often preferred for applications requiring high transparency and excellent weather resistance. Its manufacturing process also allows for thicker sheets, making it suitable for custom designs.

On the other hand, extruded acrylic tends to be more cost-effective and is typically used in applications where thickness and optical clarity are less critical. It’s easier to mold and can be produced in larger sheets, making it a versatile choice for various projects.

Impact-modified acrylic provides an additional layer of durability, making it ideal for environments prone to rough handling or potential impacts. This type of acrylic typically contains additives that enhance its resistance to shattering, without significantly compromising its clarity.

As industries continue to evolve, understanding these differences will be crucial for selecting the appropriate acrylic type to meet specific needs and requirements. With innovations in manufacturing techniques and material enhancements, the various acrylic types available in 2025 will likely offer a broader range of applications, catering to both aesthetic and functional demands.

Trends Influencing Acrylic Plastic Choices in 2025

As we approach 2025, the landscape of acrylic plastic choices is shaped by several key trends. Sustainability concerns are at the forefront, as consumers become more environmentally conscious. Manufacturers are responding by developing biodegradable acrylic alternatives and promoting recycling initiatives. This shift is not just about materials but also about the entire lifecycle of the product, influencing both design and production processes.

Another significant trend is the growing demand for customizable acrylic solutions. With advancements in technology, the ability to create tailored designs is more accessible than ever. This flexibility allows consumers to express their individuality through unique shapes, colors, and finishes. As personalization becomes a priority, brands that offer versatile options in acrylic plastic will likely stand out in the marketplace.

Tips: When choosing acrylic products, consider their environmental impacts and look for companies that support sustainable practices. Additionally, think about your personal style and how customizable acrylic solutions can enhance your decor or project. Keep an eye on emerging technologies that might offer innovative options for your acrylic needs in the near future.

Sustainable Practices in Acrylic Plastic Production and Use

Sustainable practices in acrylic plastic production have become increasingly important in recent years, especially with growing concerns about environmental impact and resource depletion. The acrylic plastics industry is exploring innovative methods to reduce waste and energy consumption, including the use of bio-based materials as alternatives to traditional petroleum-based feedstocks. These new approaches not only decrease the carbon footprint associated with production but also enhance the lifecycle of acrylic products, making them a more responsible choice for consumers and manufacturers alike.

In addition to sourcing sustainable materials, manufacturers are implementing closed-loop systems that allow for the recycling of acrylic components. This not only minimizes the amount of waste generated but also promotes the reuse of valuable raw materials. Additionally, advancements in recycling technology facilitate the repurposing of scrap material into high-quality acrylic products, further contributing to sustainability goals. By prioritizing these eco-friendly practices, the acrylic plastics industry is paving the way for a greener future, ensuring that the benefits of acrylic are realized without compromising our planet's well-being.

Related Posts

-

Why Clear Plastic is the Perfect Choice for Your Packaging Needs

-

Top 5 Uses of Clear Plastic in Modern Industries: Insights & Trends

-

2025 Top 5 Colored Acrylic Sheets for Stunning Home Decor and DIY Projects

-

2025 Guide: How to Get Plexiglass Cut to Size for Your Projects

-

What is Precision Plastics? A Comprehensive Guide to Applications and Benefits

-

Transform Your Space with Clear Acrylic Solutions for Modern Decor