As we continue to navigate the year 2025, the plastic manufacturing landscape continues to shift due to factors that include innovation, environmental regulations, and precision custom fabrication. For companies in any facet of industry, whether that be medical, automotive, electronics, consumer goods, or otherwise, the correct plastic selection for injection molding has never been more important.

With Welch Plastics as a leading plastic manufacturer in Las Vegas, we are able to provide the industry with high-performance materials utilizing sophisticated plastic manufacturing processes and techniques! This guide will detail the most widely used plastics for injection molding in 2025, what trends are emerging, and sustainable alternatives that are advancing the industry.

Why Material Selection for Injection Molding is Important?

The material selected for an injection molding project can have a major impact on the performance, durability, appearance, and sustainability of the final product. Global industries that are focused on lighter-weight, recyclable, durable plastics, therefore, knowing what trends are emerging for 2025 will be key to staying competitive.

Things to Consider When Selecting Plastics for Injection Molding

- Mechanical characteristics (tensile strength, flexibility, impact resistance)

- Thermal stability

- Chemical stability

- Surface finish and colour retention

- Regulatory approval (this is important for medical, food, and consumer safety)

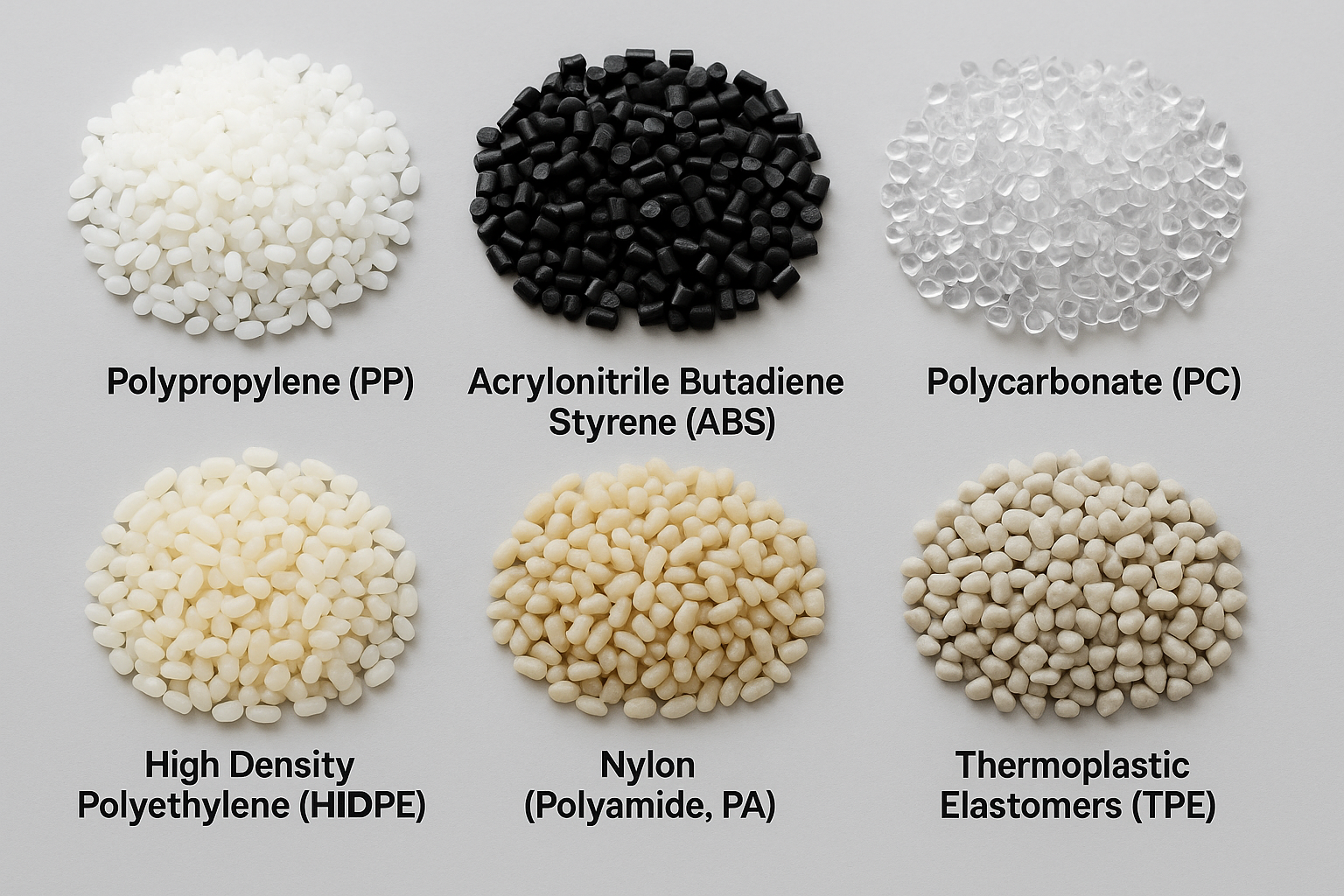

Most Common Plastics Used for Injection Molding in 2025

Below are the top-performing plastics that are currently being heavily utilized for injection molding in 2025:

1. Polypropylene (PP)

Keeping strong in 2025, polypropylene is still prized for its chemical resistance and affordability. Also, polypropylene is an extremely versatile plastic that is used in packaging, automotive components, and household goods.

What makes it number one:

- Lightweight and strong

- Acid & base resistant

- Fully recyclable

- Usage: Custom caps, containers, automotive panels.

2. Acrylonitrile Butadiene Styrene (ABS)

ABS remains a very popular thermoplastic when making plastic parts, due to its excellent impact properties and appearance. ABS is also commonly used to make housings for consumer electronics and automotive applications.

What makes it number one:

- Glossy and finished looking for quality look

- Good strength-to-weight

- Thermal unequalled properties

- Easily processed and laser-engraved to a custom design

- Usage: Computer keyboards, dashboards, medical casing.

3. Polycarbonate (PC)

Polycarbonate is an optically transparent plastic with great hit strength; we use it when strength and optical clarity are needed.

What makes it number one:

- Heat and flame resistant

- Optical grade quality

- Excellent for lightweight protection

- Usage: Safety goggles, clear cases, LED covers.

4. High Density Polyethylene (HDPE)

The reason why HDPE is always the go-to choice, especially for industrial applications, is because of its toughness and moisture resistance.

What makes it number one:

- High strength-to-density ratio

- UV resistant and resistant to a wide range of chemicals

- Non-toxic and recyclable

- Usage: Containers for industrial use, chemical storage tanks, and water pipes for buildings.

5. Nylon (Polyamide, PA)

The use of nylon is catching on for engineering applications because of its low wear properties and mechanical strength.

What makes it number one:

- High melting temperature

- Low wear and abrasion

- Ideal for high-friction applications

- Usage: Gears, bearings, mechanical bushings.

6. Thermoplastic Elastomers (TPE)

TPEs bring together many of the benefits of rubber materials with the processing benefits of a thermoplastic. For this reason, TPEs are common for soft-touch applications.

Why it’s Trending:

- Flexible and durable

- Recyclable and safe for skin contact

- Great for ergonomic products

- Used examples: grip handles and seals, and gaskets

Trends in Injection Molding Plastics

Sustainability and Bio-Based Plastics

An increase in focus on sustainability has increased demand for recycled polymers and bioplastics.

- PLA (Polylactic Acid): derived from corn starch and is primarily used in disposable and packaging applications.

- Recycled PET & HDPE: Typically used in non-critical applications to help reduce landfill waste.

- Carbon-neutral plastics: Alternatives that are made using renewable energy or carbon offsetting.

At Welch Plastics, we offer eco-friendly custom fabrication for clients who want to limit their environmental impact, without compromising quality.

Smart Plastics and Functional Fillers

It will become increasingly popular to add smart additives to plastic resins. Some examples include:

- Conductive Fillers: Used in electronics and for anti-static parts.

- UV Blockers: Used to enhance the life of outdoor components.

- Antimicrobials: Used in healthcare, hygiene, and food packaging.

By incorporating smart additives, these enhancements generate new markets for plastic manufacturers in Las Vegas and across North America that want to meet the emerging industries.

Short-Run and Rapid Prototyping with Advanced Resins

With the emergence of production on demand and rapid prototyping, almost all clients now require small-batch runs with specialty plastics.

- High-performance engineering resins such as PEEK, PSU, and PEI are now being more widely accepted and have superior performance in harsh environments.

- Welch Plastics manufactures low-volume, short-lead-time plastics – ideal for prototyping or testing market acceptance.

What’s New in 2025 – Sustainable Alternatives?

Sustainability is now required. Today’s consumers and regulators expect more environmentally friendly alternatives. Here are a few ways modern plastics are fulfilling that expectation:

Recycled Polymers

Post-consumer and post-industrial recycled plastics are being reinstated into the supply chain without losing quality.

Here are some benefits:

- Less rigid reliance on raw materials.

- More cost-efficient methods of constructing bigger runs.

- Compliance for LEED-certified and Green-certified products.

Biodegradable Plastics

Materials like PLA and PHA biodegrade, proving to be viable substitutes for traditional polymers for single-use products.

Limitations:

- Little heat resistance.

- Still needs a specific composting situation.

They can be useful for certain food packaging, agricultural applications, and disposable medical products.

Closed-loop systems manufacturing:

Modern (and of course sustainable) plastic companies in Las Vegas, like Welch Plastics, are investing money into creating closed-loop systems to reclaim, sort, and reprocess scrap material in its entirety.

- Custom Fabrication and Material Consulting

- Understanding what plastic to use for your product can be overwhelming. That’s where we come into play.

At Welch Plastics, we don’t just produce parts – we partner with you. Our team can help you with selecting the best resin based on:

- End-use environments.

- Aesthetic needs.

- Compliant requirements.

- Cost and production quantities.

Our custom plastic fabrication service includes more than just injection molding; we offer CNC routing, laser cutting, plastic thermoforming, and finishing.

WHY WELCH PLASTICS?

Welch Plastics has been a reputable plastics manufacturer in the Las Vegas market for over 30 years. We provide precise plastic manufacturing services to companies all across the United States. Whether you are a start-up creating your first product or an OEM looking to produce a large run of your product, Welch Plastics has the capabilities, knowledge, and desire to actualize your vision.

What sets us apart:

- Best equipment in injection molding.

- More sustainable materials and processes.

- Dedicated engineering and design team.

- Fast turnaround time and competitive pricing.

Final Thoughts:

Injection molding in 2025 is not just about melting some plastic and pouring it into a mold. Rather, it’s about understanding what material to use, how to optimize your approach to sustainability and a fast-changing world, and maintaining the standard of modern manufactured plastic products.

If you’re looking for a Las Vegas plastic manufacturer that provides an innovative, reliable, and socially and environmentally conscious service, Welch Plastics can ease your search.

Ready to start your project?

📞 Contact Welch Plastics for a free consultation and let’s discuss your project, the options of materials, and build the solution that works today and into the future.