In an ever-changing product development world, any speed advantage matters to start-ups. Taking a good idea and making it into a rapidly working prototype can make the difference between getting funded and not. Custom plastic fabrication services can play a crucial role in this process.

Plastic fabrication can craft prototypes quickly, and with superior quality, through techniques such as injection molding, thermoforming, CNC machining, and 3D printing; all much more rapid than any traditional method of fabrication. In this article, we will explain why custom plastic fabrication services are valuable, if not crucial, for start-ups to innovate, iterate, and scale quickly.

What is Custom Plastic Fabrication?

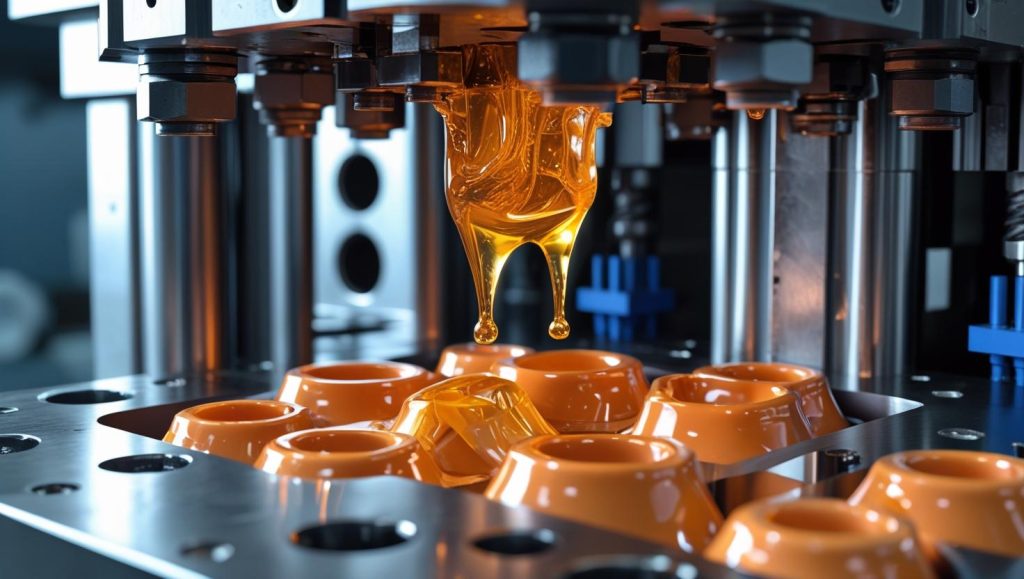

Custom plastic fabrication is the process of designing, forming, and assembling plastic to create plastic products, custom-built to order. Custom plastic fabrication is fundamentally different than mass production, which produces large production runs of identical products. Custom fabrication can produce small batches, including single batches, where the specifications are defined entirely and completely. Custom plastic fabrication utilizes multiple types of methodologies, such as:

- Injection molding

- CNC plastic machining

- Vacuum forming

- Laser cutting

- 3D printing

- Plastic welding and bonding

Each of these methodologies allows plastics manufacturers to provide custom products in the correct size, materials, and functions that you require for a prototype or even a final product.

Why Does Speed in Prototyping Matter?

Startups are built on limited resources, and time and money are likely the two most critical resources for a startup to succeed. The quicker a new business can validate with a prototype and leverage feedback to improve, the greater the odds of business success. There are compelling reasons why prototyping velocity with custom plastic fabrication is of paramount importance:

- First-mover advantages — Get to market early, so you can capture a portion of the market.

- Investor-ready — Get a prototype that works, and get credibility in the market.

- Product validation — Real-world testing will tell you if you are solving the right problem.

- Cost-effective — Iterations early on are less expensive than changing out later production runs.

Custom plastic fabrication service providers are fundamentally better suited to meet these needs as they offer flexible and fast turnaround options.

Advantages of Custom Plastic Fabrication for Startups

1. Fast Turnarounds

Plastic is machined, shaped, and molded faster than metal or glass, and thus is more consistent for fast prototyping. Tools such as additive manufacturing and CNC mean that plastic fabricators can build complex models in days – or even hours — rather than weeks!

Custom plastic fabricators also offer low-volume production runs with injection molds, and have fast tooling services, including “quick molds” just like aluminum molding, making timelines even shorter!

2. Cost-Effective Prototyping

If you are a startup that is budget-conscious, plastic fabrication is also a cost-effective solution. Plastic materials are less expensive than metals and ceramics, and processes like additive manufacturing and thermoforming can help to minimize plastic waste, thus reducing your overall cost! Another positive aspect of plastics production is that once a prototype has been fully developed, it can easily transition to low-volume production or full-scale production without significant redesign.

3. Incomparable Customization

Start-ups usually have numerous iterations of a prototype. You can make tweaks with custom fabrication. That could be dimensions, materials, features, or all at the same time. Custom plastic fabricators can offer flexibility that can’t be matched in any other way.

Want a prototype made of heat-resistant material? Pick polycarbonate or PTFE. Need a transparent part? Then acrylic, or PMMA, will do. Do you want a feature that fits together easily? Then ABS or polypropylene could work! The variety of materials in plastics is second to none.

4. Lightweight but Strong Designs

In industries like electronics, automotive, or medical devices, plastic prototypes offer strength with no weight! This is very useful when undertaking real-world applications. Be it a housing for a drone, a case for a wearable, or a medical instrument, plastic fabrication enables start-ups to achieve rigid but lightweight components that can be used in the field.

5. Integration with Modern Design Tools

Plastics fabrication lends itself seamlessly to modern digital design software (AutoCAD, SolidWorks, Fusion 360, etc.), allowing designs to be easily transferred onto CNC machines, laser cutters, or 3D printers for fabrication.

When it comes to plastics fabrication, there is no possibility of mistakes in translation between design and manufacture (that’s common to traditional production processes), and you can get to market faster going from CAD to prototype.

Injection Molding: An Excellent Transition from Prototyping to Production

Custom plastic fabrication is very beneficial for prototyping, but injection molding is important when transitioning from low-volume prototypes into production.

These are the advantages of injection molding when startups transition into manufacturing:

- Consistency: Ideal for making multiple works of the same prototype.

- Materials: Ability to be used with thermoplastics, elastomers, and other materials.

- Speed: After the mold is developed, parts can be made in seconds.

- Scale: Easily scalable from low volume to mass production.

Some custom plastic manufacturers offer hybrid processes: a mix of custom fabrication with your prototypes, and injection molding for scale. Hybrid processes are a way of providing value by reducing the friction between development stages.

Typical Uses of Custom Plastic Prototyping

Businesses and startups across an almost infinite number of markets can take advantage of custom plastic manufacturing for rapid prototyping processes.

1. Consumer Electronics

Performing rapid manufacturing and testing on cases, brackets, holders, bezels, and many more components makes sense for rapid prototypes.

2. Medical Devices

A variety of items that range from syringes, housings, and surgical instruments, where accuracy is extremely important, plastic fabricators can have amazing accuracy.

3. Automotive Startups

Custom fabrication and injection molding are helpful for automotive start-up iterations and testing, ranging from brackets to dashboard covers to panels.

4. Wearables and IoT Devices

The enclosures, clips, and fittings all use a blend of plastic machining and 3D printing in order to manufacture cheaply and quickly. Green Tech

The shift towards sustainable, bio-based, or recyclable plastics is being enhanced by rapid iteration methodologies and, likely, digital scenarios employed by sustainable startup companies.

How to Choose the Right Plastics Fabricator?

Not every plastics fabricator is going to be the best fit for a startup setting. Here are some traits to look for in the custom plastics fabricator who can fulfill your prototyping requirements:

- In-house capabilities: When we say in-house, the shop has CNC machining, 3D printing, laser cutting, and injection molding.

- Material experience: A shop that works with thermoplastics is supported by a skillful team to coach and recommend materials suitable for your application.

- Quick quoting and lead time: Startups must rely on partners who are equally fast-paced to develop their project and product cycles.

- Low minimum order quantities (MOQs): MOQs are necessary for businesses to test, develop, and prototype early concepts.

- Engineering support: From DFM (design for manufacturability) to material selection, collaboration is key.

Future Trends: AI, Sustainability, Speed

The custom plastics fabrication environment is growing rapidly. Innovation-based startups can look out for these trends in the development landscape:

- AI-based design optimization: Currently, DFM affects companies’ design process, creating a measurable reduction in prototyping cycles.

- Sustainability: recycled, biodegradable, and other low-impact plastics, bio-based, and even vegan plastics will soon be a reality.

- Digital fabrication landscape: online quoting, prompts to message with real-time collaboration have all led to unprecedented access to custom plastics.

Final Thoughts

For startups, speed and flexibility are paramount. Custom plastics fabrication is a vehicle for the innovator to turn their idea into a real prototype faster, cheaper, and accurately. Custom plastics fabricators are bringing plastics prototypes to life in the fields of life-changing wearable devices, incredible new medical devices, and smart home appliances. The choice of the right plastic and partner could make or break product scaling or product development, defect, or failure.

Plastics manufacturers and custom plastic fabricators are the silent heroes behind fast-moving, innovation-driven startups that are often the ones to coalesce around an idea or, in this case, a new product. From applied sketch to small volume injection molding, if you are ready to bring your idea to fruition, consider the innovation of custom plastics fabrication and how impactful it can be to hand a prototype faster than you could have imagined.

Contact Welch Plastics to discuss your needs for custom fabrication and see how we can help bring your ideas to life from concept to creation.